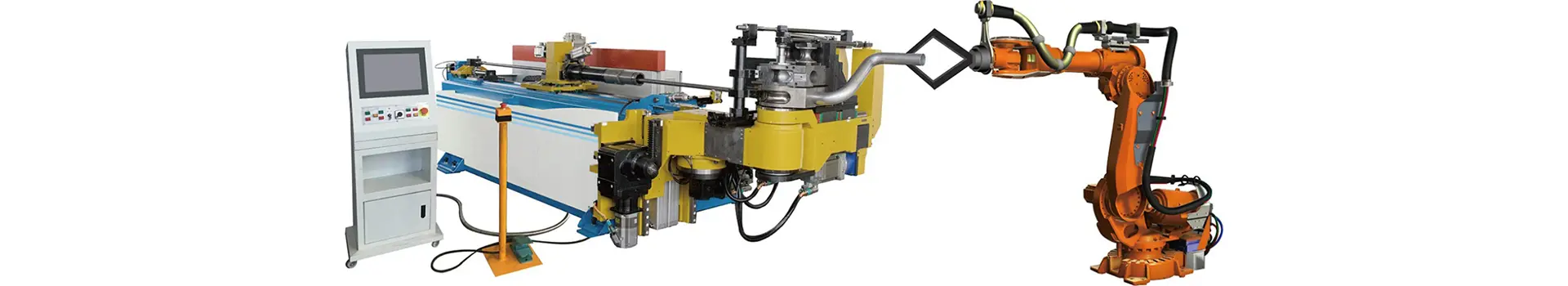

Tube bending machine 38CNC-4A-2SV

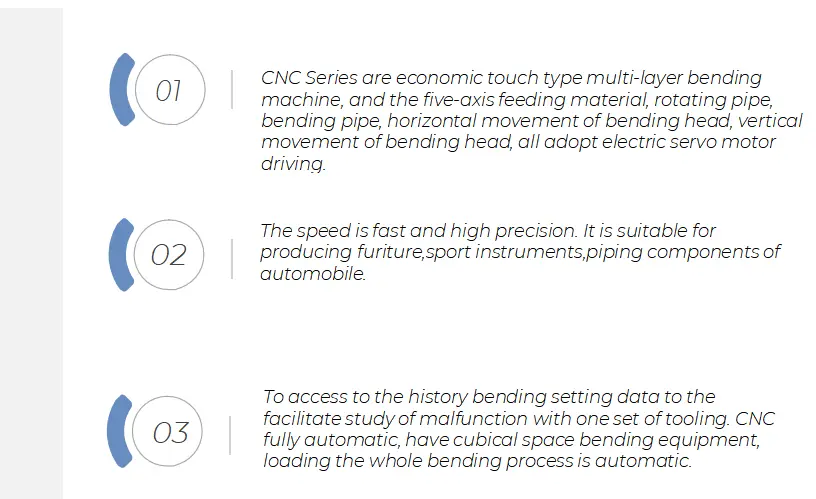

FEATURES

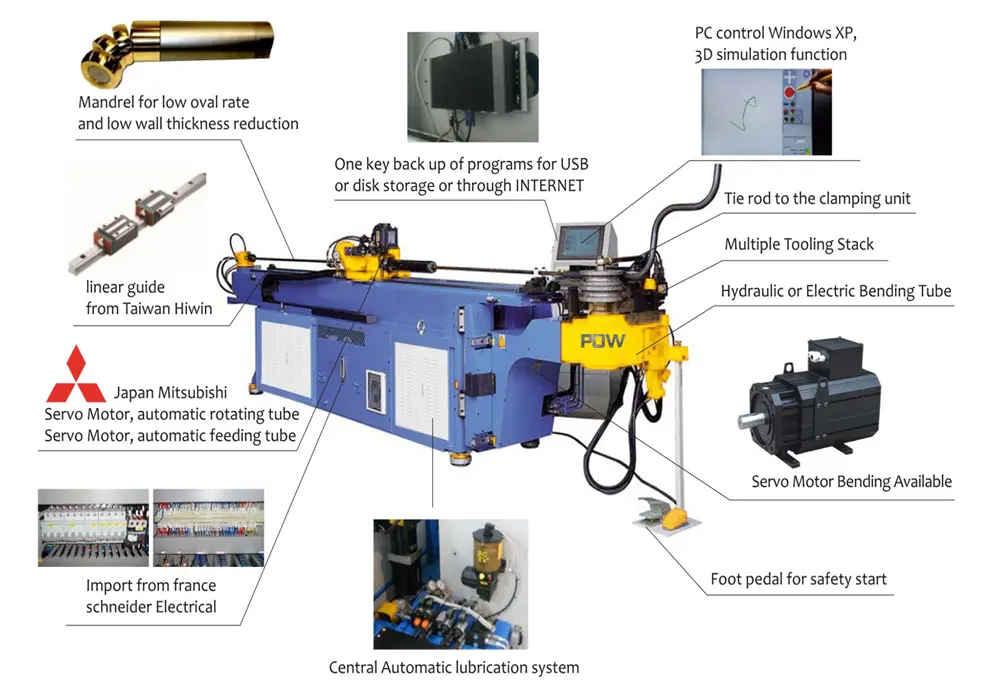

DETAILS

|

|

|

|

Servo motor from Japan Mitsubishi |

Thermal overload relay from France Schneider |

Linear guide from Taiwan Hiwin |

PARAMETER

|

No |

Name |

Unit |

Parameter |

||

|

01 |

Max bending capability:mild steel |

mm |

38*2.0 |

||

|

02 |

Min. bending radius |

mm |

R≥1.5D |

||

|

03 |

Max. Push bending radius |

mm |

5D~ |

||

|

04 |

Max. Bending radius(Standard) |

mm |

200 |

||

|

05 |

Though Effective Distance |

mm |

3200 |

||

|

06 |

Head overhang (on bending center) |

mm |

600 |

||

|

07 |

Head height (on bending center) |

mm |

130 |

||

|

08 |

Max. Bending Angle |

° |

190° |

||

|

09 |

Max. Bending Speed |

°/sec |

180 |

||

|

10 |

Bending Angle Precision |

° |

±0.1 |

||

|

11 |

Feeding Precision |

mm |

±0.1 |

||

|

12 |

Rotating-tube Precision |

° |

±0.1 |

||

|

13 |

Max rotating speed |

°/sec |

180 |

||

|

14 |

Max bending quantity in each pipe |

curve |

20 |

||

|

15 |

Hydraulic System Motor Power |

KW |

4 |

||

|

16 |

Hydraulic Pump Output Volume |

L |

19 |

||

|

17 |

Max Pressure |

Mpa |

16 |

||

|

18 |

Oil Tank Volume |

L |

About 220 |

||

|

19 |

Max bending quantity in each pipe |

curve |

40 |

||

|

20 |

Tooling Center Height |

mm |

35 |

||

|

21 |

Feeding Method |

1.clamping |

2.loosen |

||

|

22 |

Repeated Location Precision |

Bending Axis |

° |

±0.1 |

|

|

|

|

Diversion Axis |

° |

±0.1 |

|

|

23 |

Ovality rate after processed |

<8% |

|||

|

24 |

Thickness Reduction after processed |

<12% |

|||

|

25 |

Feeding Servo |

KW |

3.0 |

||

|

26 |

Rotating Servo |

KW |

0.4 |

||

|

27 |

Changing mold servo |

KW |

0.75 |

||

|

28 |

Bending Servo |

KW |

3.5 |

||

|

29 |

Gross Power |

KW |

About 12 |

||

|

30 |

Data input |

X. Y, Z coordinates or import format (can preview the 3D shape of the workpiece) |

|||

|

31 |

Data input |

Manual input or 3 coordinate input or import input |

|||

|

32 |

Storage data capacity |

100000 sets |

|||

|

33 |

Machine Voltage |

V |

As per customer’s requirements |

||

|

34 |

Machine size |

mm |

About 4200*850*1350 |

||

CONFIGURATION

|

No |

Name |

Manufacturer |

|

01 |

Industrial Personal Computer(IPC) |

Taiwan Yanhua |

|

02 |

PLC |

Japan Mitsubishi |

|

03 |

Rotating servo motor |

Japan Mitsubishi |

|

04 |

Feeding servo motor |

Japan Mitsubishi |

|

05 |

Bending servo motor |

Japan Mitsubishi |

|

06 |

Changing mold servo motor |

Japan Mitsubishi |

|

07 |

Rotating drive |

Japan Mitsubishi |

|

08 |

Feeding drive |

Japan Mitsubishi |

|

09 |

Bending drive |

Japan Mitsubishi |

|

10 |

Changing mold drive |

Japan Mitsubishi |

|

11 |

Linear Guide Rail |

Taiwan SHAC |

|

12 |

Magnetic Valve |

Yuken |

|

13 |

Flood Valve |

Yuken |

|

14 |

Oil tube |

Suzhou Kejia |

|

15 |

Oil way Board |

Taiwan Shanghong |

|

16 |

Gear pump |

Tuoli |

|

17 |

Main motor |

Wuxi Taihu |

|

18 |

Contactor |

Schneider |

|

19 |

Oil Cylinder |

Shanghai Qifan |

|

20 |

Photoelectric switch |

Japan Omron |

|

21 |

Switch power supply |

Taiwan meanwell |

|

22 |

Relay Integrated relay |

customized |

|

23 |

Reducer |

Germany Hengte |

|

24 |

Bearing |

Wahaluo |

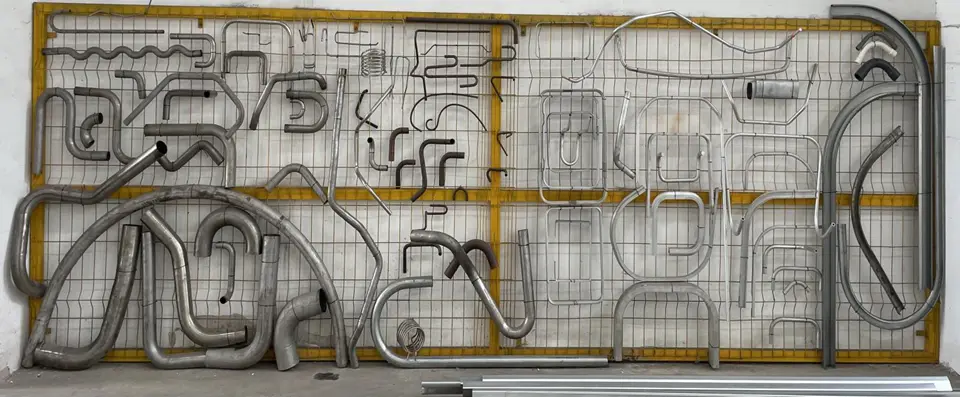

BENDING SAMPLES

TOOLING SAMPLES

PACKING

|

|

|

|

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products