The development and progress of press brakes

Press brakes have undergone significant changes since their inception, evolving from humble tools to advanced equipment that embodies high flexibility, high precision and high efficiency. The history of press brakes reflects broader trends in manufacturing technology, where the need for environmentally friendly and energy-saving solutions also has become a top priority.

Historical development of press brakes

Early machines were limited in their capabilities and often required a lot of manual labor and expertise. As the industry grew and the need for more complex shapes and designs emerged, the need for more advanced bending solutions became apparent.

The introduction of hydraulic technology in the mid-20th century marked a pivotal moment in the development of press brakes. Hydraulic press brakes provided greater power and control, allowing for more complex designs and higher productivity. This innovation laid the foundation for the modern press brakes we see today.

The advent of CNC technology in the late 20th and early 21st centuries revolutionized the bending process. CNC press brakes offer unparalleled precision and repeatability, allowing manufacturers to produce complex geometries with minimal human intervention. This shift not only increased efficiency but also reduced waste, in line with the manufacturing industry’s growing focus on environmental protection.

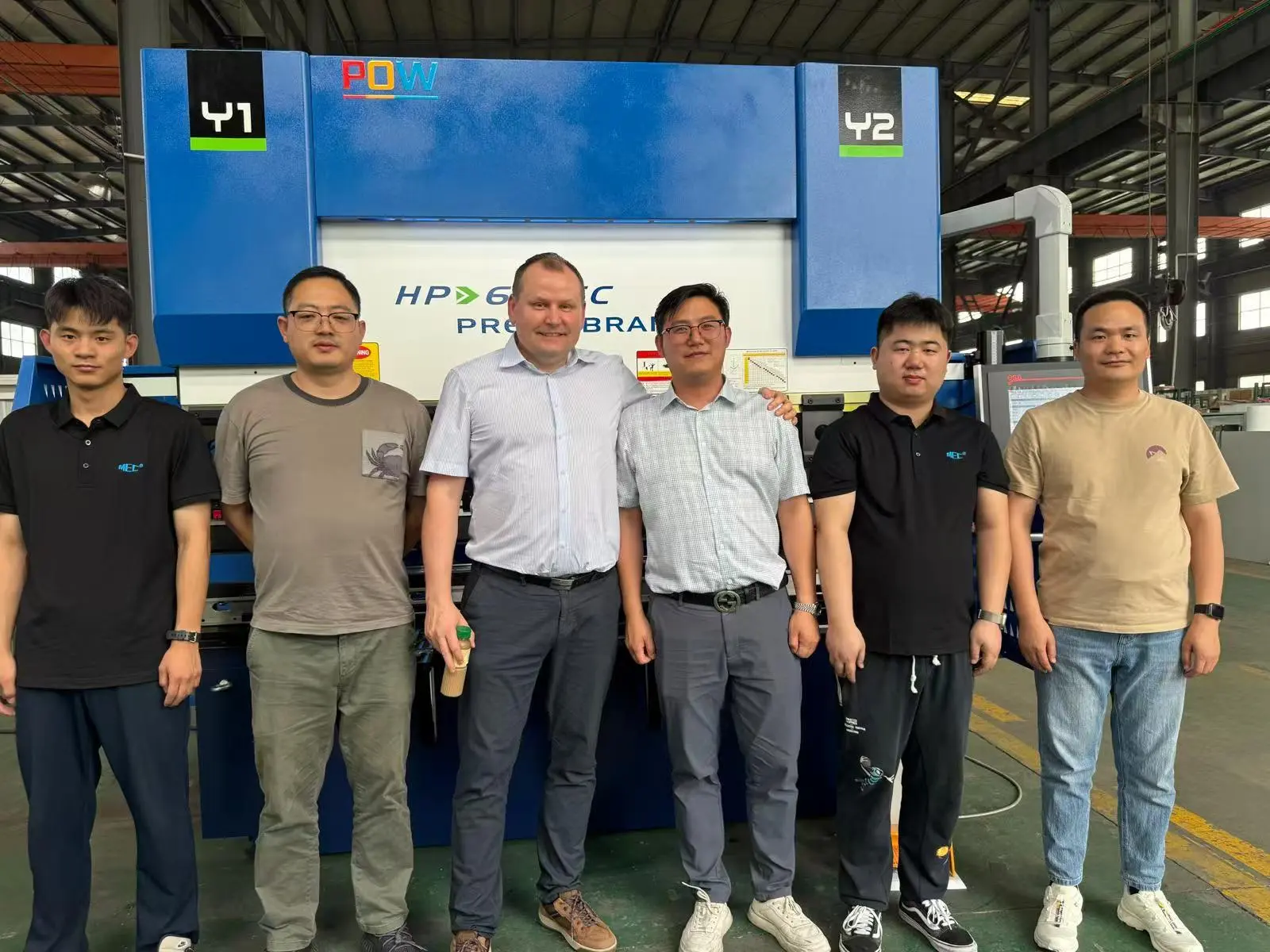

Progress of press brakes

Today’s press brakes offer several key advantages that make them indispensable in modern manufacturing.

High Flexibility: Modern press brakes are designed to handle a wide range of materials and thicknesses. This flexibility allows manufacturers to quickly adapt to changing market demands and produce customized products without extensive downtime. The ability to switch between different bending processes and materials increases productivity and reduces delivery times.

Precision: The integration of advanced technologies such as CNC and laser systems has significantly improved the accuracy of press brakes. This level of precision is critical for industries such as aerospace, automotive, and electronics, as even the slightest deviation can lead to costly errors.

High Efficiency: Modern press brakes are designed with high efficiency to minimize cycle times and maximize production output. Features such as automatic tool changers and real-time monitoring systems allow for seamless operation, reducing the need for manual intervention. This efficiency not only increases productivity but also reduces operating costs.

Energy saving: With the growing focus on sustainability, modern press brakes are being designed to be more energy efficient. Many machines incorporate energy-saving technologies such as servo motors and optimized hydraulic systems, which significantly reduce energy consumption. This not only reduces operating costs but also complies with global environmental efforts.

Environmental Protection: The shift toward eco-friendly manufacturing practices has influenced the design of contemporary press brakes. Many manufacturers now prioritize the use of recyclable materials and implement processes that reduce waste. Additionally, energy-efficient machines help reduce carbon footprint, making them a more sustainable choice for manufacturers.

All in all, the history of press brakes shows a remarkable evolution driven by technological advancements and changing industry needs. The advantages of modern press brakes - high flexibility, high precision, high efficiency, energy saving and commitment to environmental protection - make them an indispensable tool in today’s manufacturing sector. As the industry continues to develop, press brakes will undoubtedly play a key role in shaping future production.1.2.3.4.5.

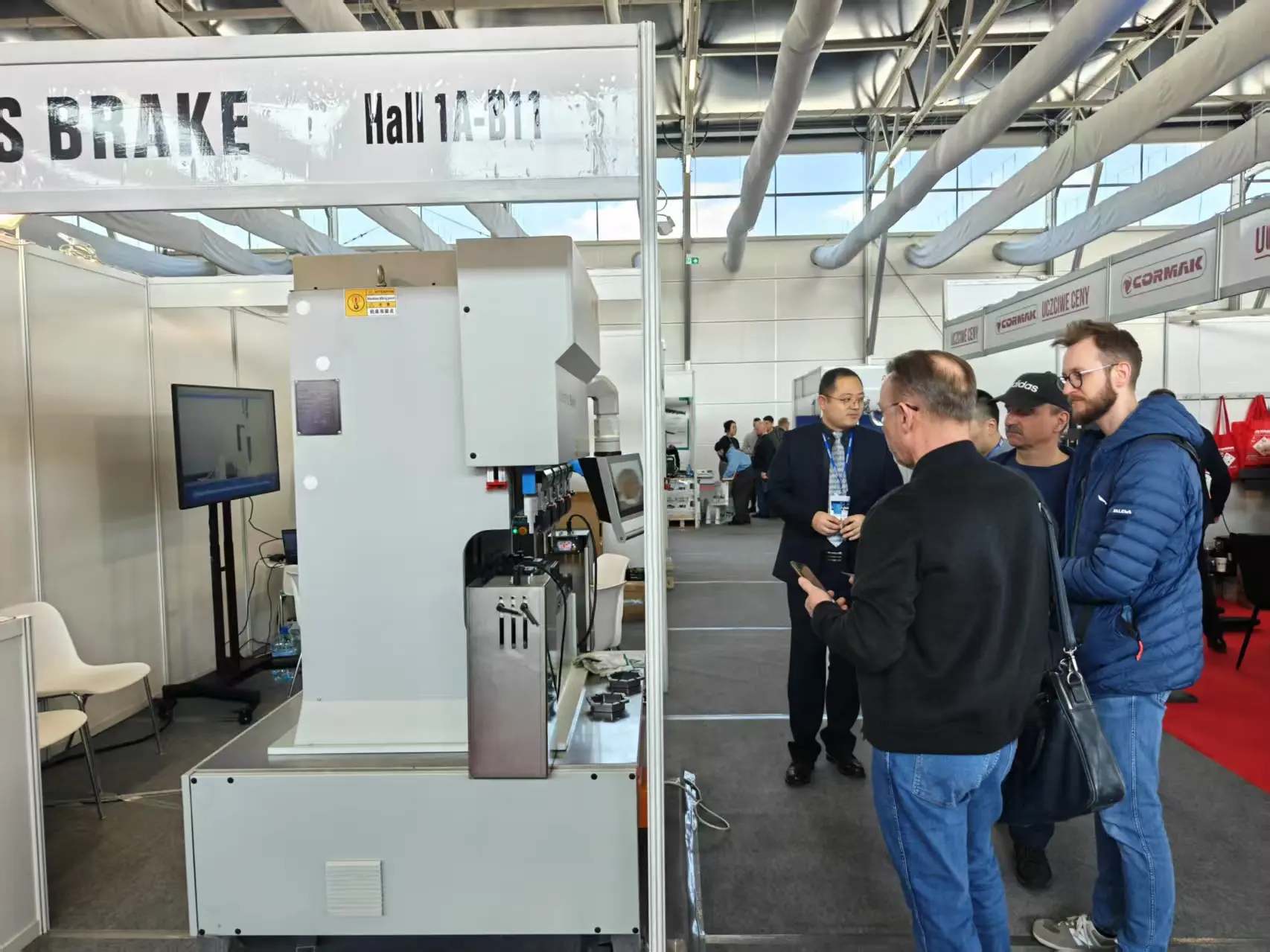

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products