Laser Welding

SCOPE OF APPLICATION

●0.4~4mm low carbon steel, stainless steel, non-ferrous metal welding

FEATURES

PARAMETER

|

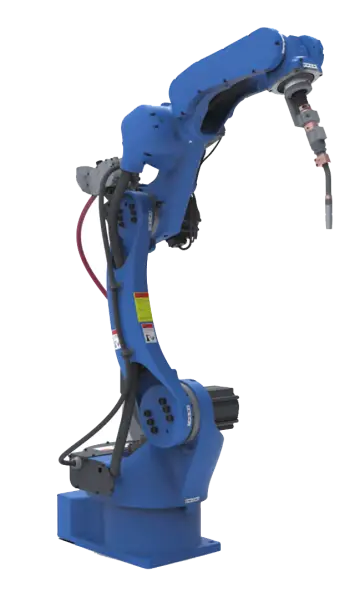

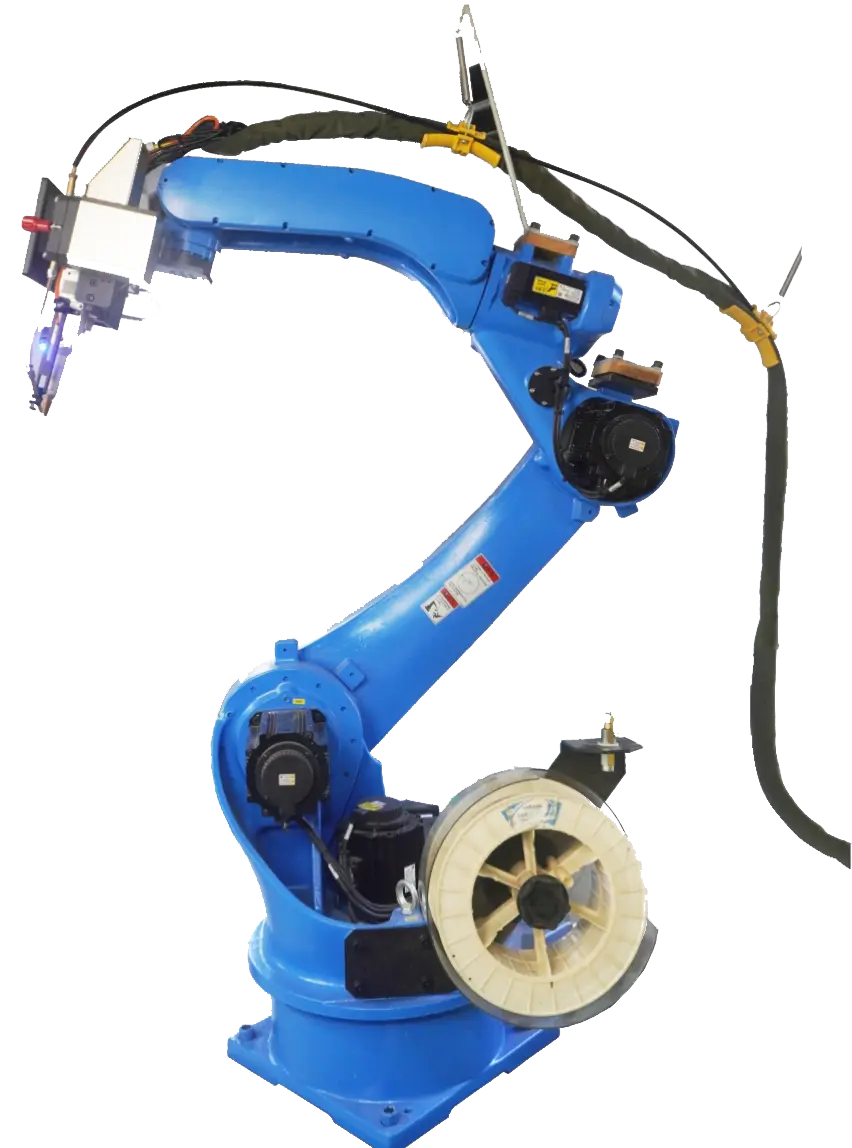

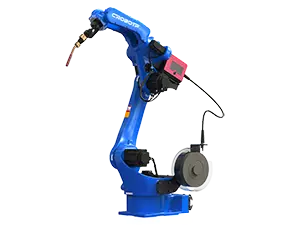

CRP-RH14-10-W Welding robot |

|||

|

Arm Type |

Vertical Multi - Joint |

||

|

Degrees of Freedom of Movement |

6 - axis |

||

|

Maximum Payload |

10KG |

||

|

Max. Stroke |

Axis 1 |

Front - Mounted / Inverted: - 167° - 167°, Wall - Mounted: - 30° - 30° |

|

|

|

Axis 2 |

0° - 175° |

|

|

|

Axis 3 |

- 80° - 150° |

|

|

|

Axis 4 |

- 190° - 190° |

|

|

|

Axis 5 |

- 105° - 130° |

|

|

|

Axis 6 |

- 210° - 210° |

|

|

Max. Speed |

Axis 1 |

169°/S |

|

|

|

Axis 2 |

169°/S |

|

|

|

Axis 3 |

169°/S |

|

|

|

Axis 4 |

280°/S |

|

|

|

Axis 5 |

240°/S |

|

|

|

Axis 6 |

520°/S |

|

|

Allowable Torque |

Axis 4 |

10N.m |

|

|

|

Axis 5 |

10N.m |

|

|

|

Axis 6 |

3N.m |

|

|

Allowable Inertia Torque |

Axis 4 |

0.25kg.m² |

|

|

|

Axis 5 |

0.25kg.m² |

|

|

|

Axis 6 |

0.05kg.m² |

|

|

Repeatability Positioning Accuracy |

±0.08mm |

||

|

Maximum Reach |

1440mm |

||

|

Weight of the Robot |

170KG |

||

|

Installation Method |

Floor - Mounted, Ceiling - Mounted |

||

|

Installation Environment |

Ambient Temperature |

0 - 45°C |

|

|

|

Relative Humidity |

20 - 80% (Non - Condensing) |

|

|

|

Vibration |

Below 0.5G |

|

|

|

Others |

The robot installation site must be away from: Flammable or corrosive liquids or gases, electrical interference sources |

|

|

IP Rating |

Robot body: IP54, Wrist: IP67 |

||

|

Features |

Compact structure, high - speed, high - precision, high - expandability, easy to operate |

||

|

Application Scenarios |

Welding, cutting, assembly, handling, marking, grinding |

||

|

CRP-E60-G4 Electrical cabinet |

|

|

Input Power Supply |

Three - phase 380V, ± 10%, 50 - 60HZ; Power: 5KVA |

|

Control System and Servo |

Drive - control Integrated Core |

|

Number of Control Axes |

6 + 4 Axes (Standard Configuration is 6 Axes, External Axes Need to be Optional) |

|

Interfaces |

Digital I/O Interface, 20 - way Input/20 - way Output (2 Inputs/2 Outputs Occupied by Dual - station Box), COM Expandable |

|

|

4 - way 0 - 10V Analog Output, 12 - bit Precision, COM Expandable |

|

|

Dual - channel Encoder Signal Interface, RS232/485 Interface |

|

|

Ethernet Interface |

|

|

Dual USB Interfaces |

|

Robot Safety |

External Emergency Stop, Anti - collision, Safety Pin - out and Other Interfaces; MC Safety Loop, Servo Softening, etc. |

|

Reserved Dedicated Interfaces |

Arc Welding Dedicated Interface, Workstation Interface, Remote Host Interface |

|

Pre - installed Software Package |

Arc Welding Software Package |

|

Others |

Built - in PLC, Power - off Regeneration, Point - seeking Hardware and Software, Arc Tracking and Accessories (Optional), Vision Software (Optional), Laser Tracking Software (Optional), etc. |

|

Robot Cable Length |

Standard - equipped X1, X2 Cables, Cable Length 5m |

|

Workstation Box |

Standard - equipped with Two Workstation Operation Boxes, Cable Length 5m |

|

Operating Environment |

Temperature: 0 - 45°C, Humidity: 20% - 80% (No Frost), Vibration: Below 0.5G |

|

Dimensions (mm) |

550×785×410 |

|

Weight |

65KG |

|

IP Rating |

IP51 |

|

Laser Welding Machine |

|

|

Model |

SF1500HWM Oscillating Laser Welding Machine |

|

Input Power Supply |

3 - phase 380V ± 15%, 50/60HZ |

|

Input Power |

9KW |

|

Laser |

RFL - C1500 |

|

Laser Wavelength |

1080nm |

|

Optical Fiber Length |

10m |

|

Optical Fiber Core Diameter |

50μm |

|

Welding Machine Speed Range |

0 - 120mm/s |

|

Operating Environment Temperature Range |

- 10 - 40°C |

|

Recommended Welding Thickness |

0.5 - 4mm |

|

Cooling Method |

Water - cooled |

|

Dimensions |

954X715X1080mm |

|

Total Weight of the Machine |

220KG |

|

Consumables |

Protection Lens: 1 - week lifespan; Welding Nozzle: lifespan over one month |

|

Total Power |

9KW |

|

Filler Wire Material |

Standard - equipped with 1mm gas - shielded welding wire and 1mm stainless - steel wire; other material specifications of welding wires are optional |

|

Accessory parameters |

|

|

Teach Pendant |

8 - inch TFT - LCD, keyboard + touchscreen, mode selection switch, safety switch, emergency stop button, cable length 6m |

|

Operation Box |

With emergency stop, start, pause, enable functions, cable length 5m, 2 standard - equipped |

|

Interconnection Cable between Electric Cabinet and Main Body |

5m |

|

Others |

Robot isolation installation kit |

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products