Hydraulic CNC press brake for metal bending

Product Details

Fast clamp

Universal top punch and 2V self-aligned bottom die

High resolution linear encoder

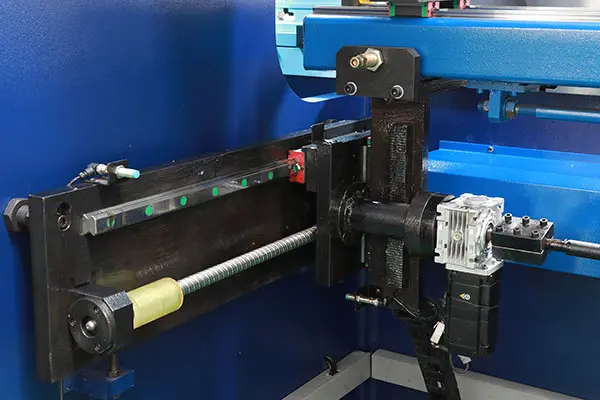

Linear guide ball screw back gauge

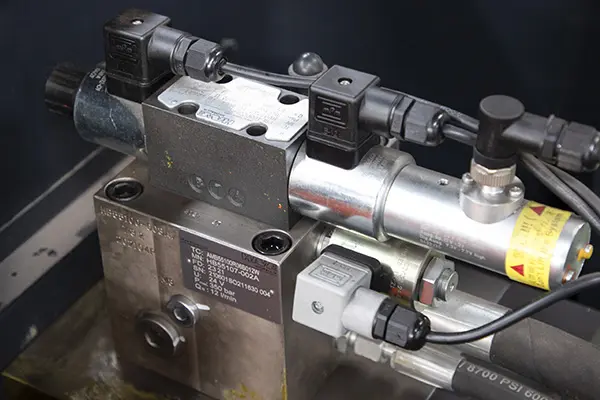

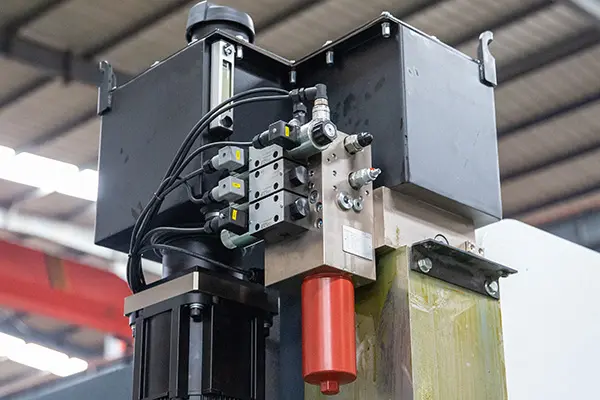

World first class hydraulic valves

Mechanic crowning device

Sleeve type Pipe connection

3 stations backgauge fingers

Linear guide front support

Schneider electric components

Optional Parts

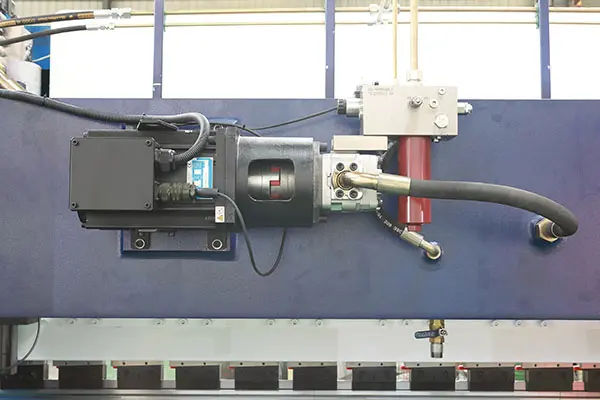

Servo pump hydraulic system

1. No pipe connection,70-80% hydraulic oil less, less hydraulic problems;

2. 60-70% energy saving,30% faster, 15% noise less.

Servo main motor

Automatic Z1,Z2 backgauge fingers

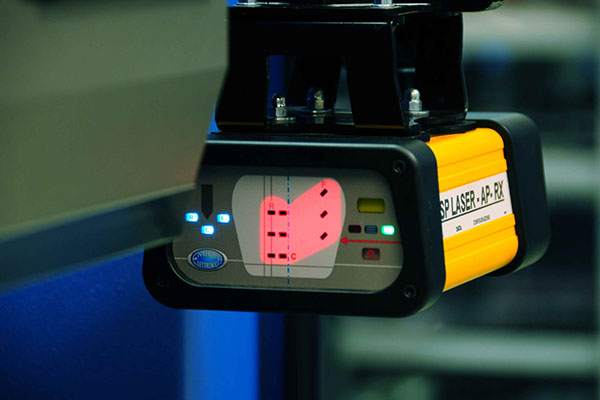

Laser protection

CE Standard 5 points valve monitoring

Back door

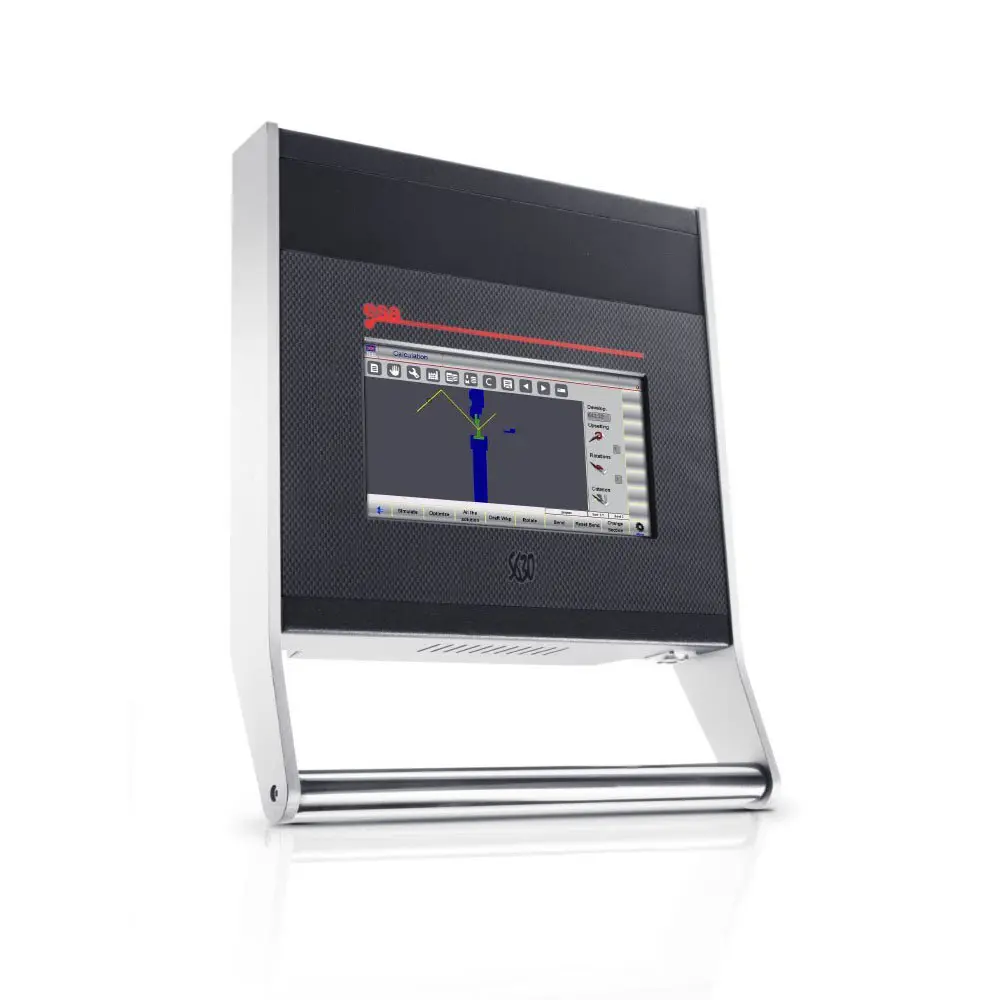

CNC System

CYBELEC CT8

CYBELEC CT12

ESA 630

ESA 860

DELEM DA53T

DELEM DA58T

DELEM DA66T

Specification

|

Item |

Unit |

Specification |

|||||||

|

Press power |

KN |

400 |

80 |

100 |

160 |

200 |

250 |

320 |

|

|

Working length |

mm |

1600 |

2500 |

3200 |

4000 |

3200 |

4000 |

4000 |

|

|

Side column distance |

mm |

1200 |

2000 |

2700 |

3500 |

2700 |

3500 |

3500 |

|

|

Stroke |

mm |

150 |

200 |

200 |

200 |

200 |

250 |

300 |

|

|

Max open height |

mm |

400 |

450 |

480 |

480 |

480 |

520 |

575 |

|

|

Throat depth |

mm |

280 |

350 |

400 |

400 |

400 |

400 |

400 |

|

|

Ram speed |

Approach |

mm /s |

150 |

175 |

190 |

190 |

170 |

140 |

120 |

|

Working |

mm /s |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

Return |

mm /s |

110 |

120 |

160 |

160 |

140 |

110 |

110 |

|

|

Main Motor |

KW |

4 |

7.5 |

7.5 |

11 |

15 |

18.5 |

22 |

|

The machine can process a range of materials, including stainless steel, brass, copper, alloy, and carbon steel, making it suitable for various applications and industries. POW press brakes can improve your bottom line by giving you higher quality parts, shorter cycle times, and lower operating and maintenance costs. Whether your application requires bending simple shapes or complex parts, POW has a press brake to fit your needs and budget. POW press brakes are designed for reliability, repeatability, precision, performance, and ease of operation.

We offer a wide range of press brakes with features and options that can be tailored to different manufacturing environments. Each series offers a range of lengths and tonnages. POW can also custom design and build a press brake to your exact needs.

Press Brake

Press Brake CNC Laser

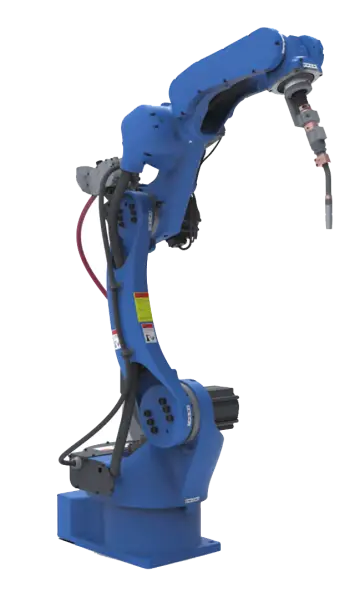

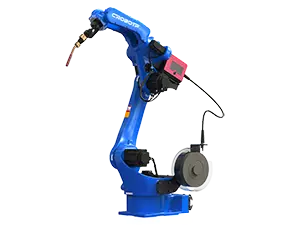

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products