Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the world of rolling, precision is key. Expert Jason Rivers emphasizes, "A good Rolling Machine can elevate your rolling game." Rolling machines simplify the process, delivering uniform cones with ease. However, achieving perfection requires practice and attention to detail.

Many enthusiasts start with high hopes but face challenges. Misalignment or excess material can lead to imperfect cones. It's essential to understand the machine fully. Knowing how to adjust settings can make a significant difference.

While rolling machines are helpful, they aren't infallible. Users must learn to identify flaws and adjust accordingly. The right technique combined with the Rolling Machine can produce excellent results. Embrace the journey, learn from mistakes, and refine your skills. This approach will enhance your rolling experience and lead to satisfaction.

A rolling machine is a useful tool for achieving perfectly rolled cones. Understanding the components is crucial. A typical rolling machine consists of a base, a cone holder, and an adjustment mechanism. The base stabilizes the machine during use. It ensures everything stays in place. The cone holder cradles the paper and prepares it for filling.

Users should pay attention to the adjustment mechanism. It controls the tightness of the roll. Too loose can mean an uneven burn. Too tight may restrict airflow. Finding the right balance is an art. Beginners might struggle with this process. It takes practice to master the technique. You might find some rolls falling apart. This failure can be frustrating but allows for growth.

Moreover, not all materials work the same way. Different rolling papers behave differently. Some are thin and delicate, while others are thick and sturdy. Experimenting with various types can lead to surprises. It can take time to identify the best combination for your preferences. Embrace these challenges as part of your journey to rolling mastery.

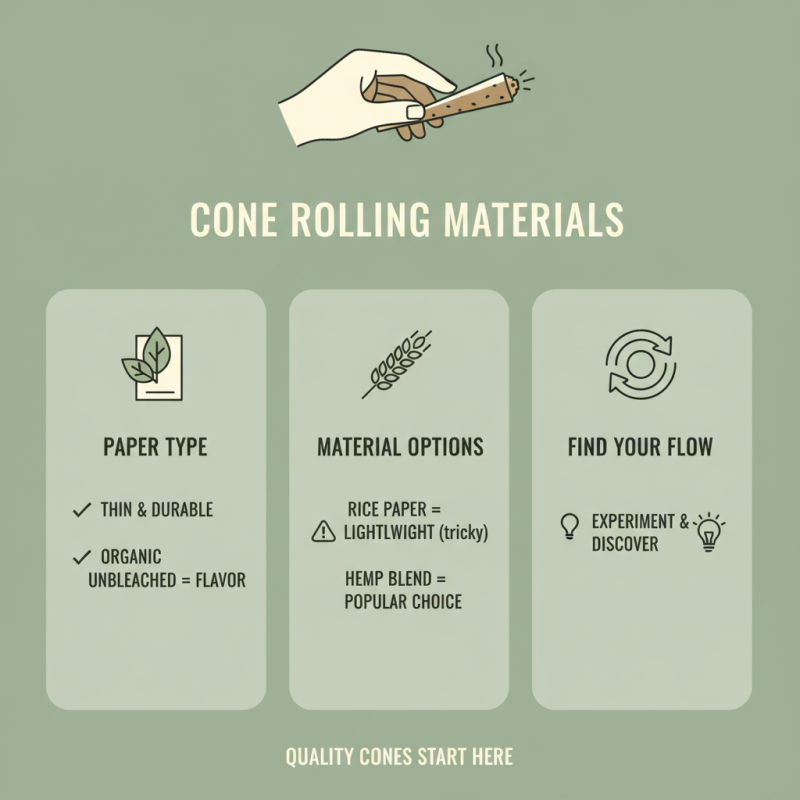

Choosing the right materials for cone rolling can greatly impact the quality of your cones. Start with the paper. Look for thin but durable options that hold their shape well. Organic unbleached papers offer a nice balance of flavor and performance. Some prefer rice papers for their lightweight nature, but they can be tricky to work with. Experiment to find your favorite.

Next, consider the filler material. Finding the right consistency is key. Too dry, and it won’t stick together. Too moist, and it may clump. Aim for a texture that feels just right between your fingers; it should be easily packable yet not overly sticky. You may find yourself testing different blends to achieve the perfect roll.

No one gets it right every time. You may end up with uneven cones. That's part of the learning curve. Take notes about what worked and what didn’t. Adjust your technique based on your observations. Rolling cones can be a fun process, but also a bit frustrating at times. Embrace the imperfections and keep refining your materials and methods.

Using a rolling machine simplifies the process of making cones. It ensures a consistent shape every time. Follow this step-by-step guide for the best results.

Begin by preparing your materials. Place the paper cone in the machine. Make sure it sits snugly. Add your chosen filling evenly. Don't overpack; it can lead to issues. Close the machine carefully. Pay attention to the alignment; it's crucial for even rolls.

Tips: Use a finer grind for a smoother fill. This helps avoid clogs and ensures a better burn. Clean the rolling machine regularly to maintain its functionality. Dust and residue can affect performance, leading to a messy result.

Once you close the machine, apply gentle pressure. Too much force can damage the cone. After rolling, check for any imperfections. They can impact the experience. If you see uneven edges, you might want to try again. Practice is key for achieving perfection. Adjust your technique and materials based on the results you observe.

| Step Number | Description | Time Required | Tips |

|---|---|---|---|

| 1 | Gather materials: rolling machine, paper cones, and your preferred herbal blend. | 5 minutes | Make sure you have everything within reach. |

| 2 | Fill the machine with your herbal blend evenly across the length. | 2 minutes | Do not overfill to prevent clogging. |

| 3 | Close the rolling machine securely and begin rolling. | 1 minute | Roll slowly for better results. |

| 4 | Remove the rolled cone and secure the end. | 1 minute | Tap the cone gently to pack it if necessary. |

| 5 | Enjoy your perfectly rolled cone! | Instant | Store any unused materials safely. |

Rolling cones perfectly can be challenging. Many beginners make common mistakes that can affect the final product. One frequent error is packing the material too tightly. This can lead to uneven burns and clogged airflow. Instead, aim for a balanced amount. It’s better to leave some space for air circulation.

Another mistake is overlooking the cone’s shape. Not all machines roll cones the same way. Some might produce a cone that’s too narrow. To avoid this, adjust the machine settings before use. Pay attention to how the material moves through the machine. With a little practice, you’ll figure out what works best for you.

Tips for rolling with a machine include ensuring the material is adequately ground. Too coarse can lead to poor results. Also, try rinsing your hands before handling the rolling paper. This can reduce static and make the process smoother. Finally, don’t rush. Taking your time can lead to better-rolled cones. Reflect on what doesn’t work, and refine your technique.

Maintaining your rolling machine is crucial for achieving perfectly rolled cones. Regular cleaning is one way to ensure longevity. After each use, disassemble the machine and wipe down all components. Dust and residue can lead to mechanical issues, affecting performance. Don’t skip this step. Some users may overlook deep cleaning. This neglect can lead to stuck pieces or clogs.

Another important aspect is lubrication. A few drops of oil on moving parts can make a big difference. However, knowing when to lubricate requires attention. Too much oil can attract dirt and grime, while too little can cause excessive wear. It's a delicate balance. Schedule maintenance check-ups at regular intervals to keep everything running smoothly.

Lastly, store your rolling machine properly. A damp environment can lead to rust, damaging metal parts. Consider keeping it in a cool, dry location. Some might forget this simple step, leading to premature wear. Be mindful of how and where you store your equipment. Small details matter in maintaining your rolling machine's performance and lifespan.