Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

Using a rolling machine can significantly enhance your experience, whether you are a seasoned user or new to the process. Mastering the art of rolling is essential for achieving the perfect roll, ensuring even airflow, and maximizing the effectiveness of your materials. In this guide, we will explore the top 10 tips for using a rolling machine effectively, which will help you to streamline your rolling technique and improve your outcomes.

The rolling machine is designed to make the rolling process smoother and more efficient. However, knowing how to operate it properly can make all the difference in your results. By adopting the right techniques and maintaining your machine, you can enjoy a better rolling experience and produce consistently high-quality results. Whether you are preparing for a social gathering or simply enjoying a moment of relaxation, these tips will empower you to utilize your rolling machine to its fullest potential. Let's delve into these essential strategies to elevate your rolling game.

Understanding the anatomy of a rolling machine is crucial for users looking to optimize their rolling process. A typical rolling machine comprises several key components: the feed system, rollers, and the output mechanism. The feed system is responsible for guiding the material into the machine. According to a report by the American Society of Mechanical Engineers, the efficiency of the feed system can significantly impact the overall operational effectiveness, with optimal designs reducing material waste by up to 15%.

The rollers, which are the heart of the rolling machine, must be crafted from high-quality materials to withstand the pressures of rolling while delivering a consistent thickness. Data from the International Journal of Manufacturing Technology highlights that the roller material can influence the output quality by affecting the uniformity of the final product. In addition, rollers can be adjusted for different applications, making an understanding of their functionality vital for users aiming for precision in their work.

Lastly, the output mechanism plays a pivotal role in ensuring the product is properly discharged without damage. Proper alignment and calibration are essential to prevent jams and ensure smooth operation. According to industry statistics, improper alignment of the output can lead to downtime of approximately 20%, underscoring the need for regular maintenance and user familiarity with the rolling machine’s components. By prioritizing these aspects, users can enhance their overall effectiveness and efficiency in utilizing rolling machines.

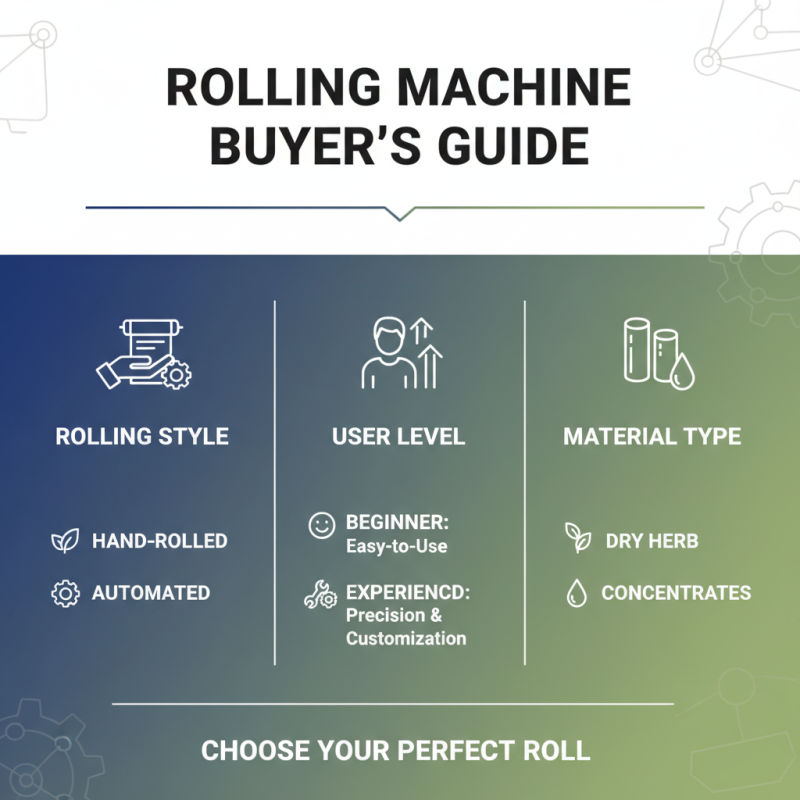

When choosing the right rolling machine, it's essential to consider your specific needs and preferences. Different machines cater to various styles of rolling, such as hand-rolled, automated, or those designed for specific materials. Assess your experience level and frequency of use; for instance, beginners might benefit from user-friendly options, while experienced users could opt for more advanced features that allow for precision and customization.

Tip: Look for a rolling machine that offers adjustable settings to accommodate different rolling styles. This ensures versatility and enhances your overall rolling experience. Additionally, consider the size and portability of the machine if you plan to use it in various locations.

Another important factor is the material compatibility of the rolling machine. Some machines are designed to work best with specific types of rolling papers or wraps. If you have a preferred material, make sure the machine can accommodate it effectively.

Tip: Always check for ease of cleaning and maintenance when selecting a machine. A device that is easy to clean will save you time and effort, allowing you to enjoy your rolling experience without the hassle.

When it comes to mastering the correct techniques for loading and operating a rolling machine, preparation is key. Start by ensuring that you have all the necessary materials organized and accessible. This includes the rolling paper or material, the rolling machine itself, and any desired fillers. Familiarize yourself with the components of the machine, as understanding its specific features can enhance your efficiency. Properly aligning your materials within the machine is crucial; take your time to ensure everything is positioned correctly to avoid jams or uneven rolls.

Once the materials are loaded, operate the rolling machine with a steady and controlled motion. Applying even pressure while rolling is essential for achieving a well-formed product. Be mindful of the speed at which you roll; too fast can lead to complications, whereas a slower pace can ensure precision. If you encounter any resistance, stop and double-check the loading to ensure everything is appropriately set. Mastering these techniques will ultimately lead to a smoother experience, enabling you to maximize the effectiveness of your rolling machine.

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Always clean the machine before use. | Prevents contamination and ensures smooth operation. |

| 2 | Check all components for wear and tear. | Reduces risk of malfunctions during operation. |

| 3 | Use the right type of rolling medium. | Ensures optimal performance and product quality. |

| 4 | Set proper speed and pressure settings. | Enhances efficiency and prevents damage to materials. |

| 5 | Avoid overloading the machine with materials. | Prevents jams and extends machine lifespan. |

| 6 | Utilize safety gear when operating. | Ensures operator safety during use. |

| 7 | Regularly lubricate moving parts. | Reduces friction and enhances performance. |

| 8 | Train operators thoroughly on machine use. | Improves operational efficiency and safety. |

| 9 | Monitor the machine during operation. | Ensures any issues are addressed immediately. |

| 10 | Perform routine maintenance as recommended. | Maximizes the machine's lifespan and reliability. |

When using a rolling machine, avoiding common mistakes can significantly enhance your experience and outcomes. One frequent error is overloading the machine with too much material. This can lead to uneven rolls and damage to the machine itself. It's essential to understand the machine’s capacity and to work in manageable portions. Always ensure that the material is evenly distributed before starting the rolling process to achieve a uniform result.

Another critical mistake is neglecting to clean the rolling machine regularly. Residue from previous sessions can affect performance and taste. Make it a habit to clean your machine after each use, ensuring that all parts are free from debris. Additionally, not adjusting the machine settings according to the type of material being used is a common oversight. Different materials require different pressure and settings for optimal results, so take the time to make these adjustments for the best experience.

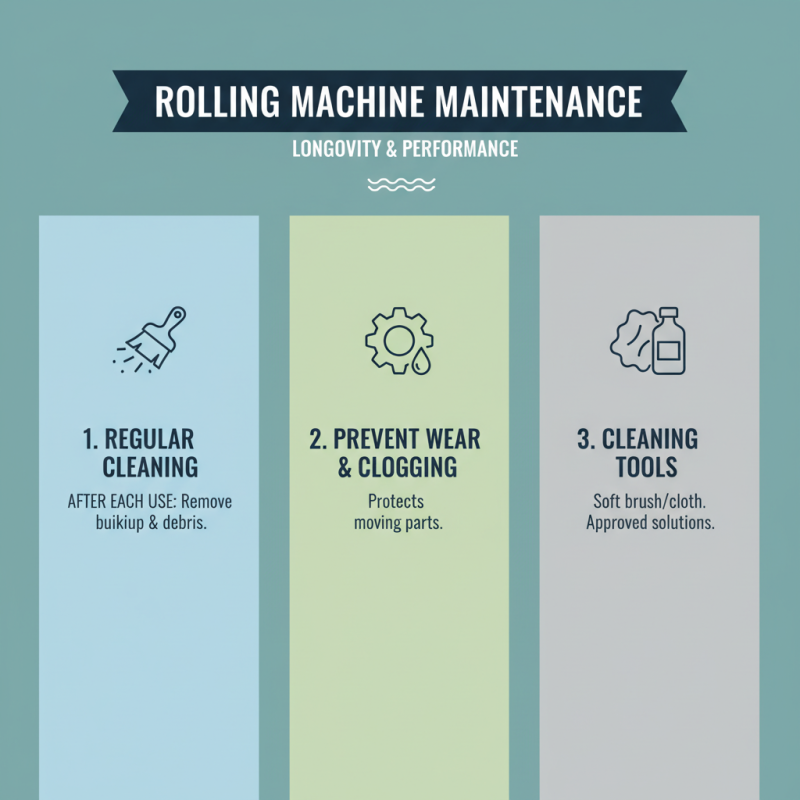

Maintaining your rolling machine is essential for ensuring its longevity and optimal performance. Regular cleaning is a fundamental aspect of maintenance. After each use, it is important to remove any buildup of materials and debris that may accumulate in the machine's components. This not only prevents clogging but also minimizes the risk of wear and tear on moving parts. Utilize a soft brush or cloth for sensitive areas, while more stubborn residues can be addressed with appropriate cleaning solutions that won’t damage the machine.

Another key element of maintenance is proper lubrication. Lubricating the moving parts of your rolling machine reduces friction and prevents overheating, which can lead to mechanical failure over time. A regular schedule should be established for this process, ideally aligning with the frequency of use. Always refer to the manufacturer’s guidelines for the appropriate type of lubricant to use, as well as the correct intervals for application. Additionally, it’s crucial to inspect the machine regularly for any signs of damage or wear, allowing for timely repairs and ensuring that the machine remains in prime working condition.