Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the competitive landscape of manufacturing, optimizing the Fiber Laser Welding Machine is crucial. Efficiency directly impacts production time and operational costs. Many businesses overlook simple adjustments that can enhance performance.

Understanding the nuances of your Fiber Laser Welding Machine can lead to significant improvements. For instance, proper maintenance is often neglected. Operators can benefit from regular checks to ensure optimal functionality. Small changes in settings may yield better results.

Embracing innovations and techniques can be beneficial. However, it's important to reflect on what works and what doesn't. Sometimes, the most advanced technologies aren’t the answer. Instead, revisiting fundamental practices can reveal untapped potential. In this article, we will explore essential tips to maximize your Fiber Laser Welding Machine efficiency.

Fiber laser welding machines offer high precision and efficiency for metal fabrication. These machines use a focused beam of light to create strong welds, making them ideal for a variety of applications. Their ability to minimize heat distortion is a significant advantage. This feature enhances the quality of the weld, especially in thin materials.

To maximize your fiber laser welding machine's efficiency, consider the following tips. First, proper lens cleaning is crucial. A dirty lens can degrade performance and lead to wasted time. Regularly inspect and clean the optics to maintain effectiveness.

Another tip is to optimize your settings. The right speed and power levels ensure better penetration and reduce the need for rework. Test different configurations to find the ideal parameters. Sometimes, what works best isn't immediately clear. Experimentation can lead to improved results.

Stay aware of your machine's maintenance needs. Neglecting routine checks can cause downtime or unexpected failures. Monitoring performance often highlights areas for improvement. By actively engaging with these details, you can enhance your welding operation.

Maintaining optimal settings for your fiber laser welding machine is crucial for achieving higher efficiency and quality. Proper focus settings can significantly impact the weld characteristics. According to industry reports, a misaligned focus can lead to up to 30% increased material stress and decreased joint strength. Ensure that the focal point aligns well with your material's surface for improved penetration and fusion.

The adjustment of power settings is another essential factor. Many operators overlook the power modulation needed for varying material types. Incorrect settings can waste energy, leading to ineffective welds. Studies show that achieving 95% efficiency in power usage requires careful calibration, especially for diverse materials. It’s vital to regularly check these parameters to maintain consistent quality and avoid unnecessary waste.

Temperature management plays a critical role too. If the material heats too quickly, it may warp or distort. Maintaining an ideal temperature range can result in better structural integrity. Some professionals recommend using thermal cameras to monitor the weld area continuously, ensuring you stay within the optimal range. Neglecting these details can lead to costly reworks and project delays, emphasizing the importance of maintaining optimal settings in every welding operation.

Routine maintenance and calibration are crucial for optimizing your fiber laser welding machine's efficiency. Regular check-ups help ensure the machine runs smoothly. Schedule weekly inspections to assess key components like lenses and mirrors. Cleaning these parts prevents debris buildup that can affect performance. A simple cloth and appropriate cleaning solution are often enough.

Calibration is another essential aspect. Make it a point to check alignment frequently. Misalignment can lead to inconsistent welds, which waste time and resources. Adjust settings based on materials used; different metals may require various configurations. Sometimes, an unexpected issue arises, even with proper maintenance. Identify these problems quickly to avoid longer downtimes.

Pay attention to the cooling system as well. Overheating can interrupt operations and damage components. Ensure that cooling fluids are within the recommended levels. If fluid leaks occur, it is important to address them promptly. These small details can impact overall machine efficiency significantly. Regularly reviewing your maintenance routine will reveal areas for improvement.

| Tip Number | Maintenance Task | Frequency | Estimated Time (Hours) | Impact on Efficiency |

|---|---|---|---|---|

| 1 | Clean Focusing Lens | Weekly | 0.5 | High |

| 2 | Check and Replace Cooling Fluid | Monthly | 1 | High |

| 3 | Inspect and Clean Nozzle | Weekly | 0.25 | Medium |

| 4 | Calibrate Laser Power | Quarterly | 2 | Very High |

| 5 | Check Beam Alignment | Monthly | 1.5 | High |

| 6 | Inspect Wiring and Connections | Bi-Annually | 1 | Very High |

| 7 | Update Software | As Needed | 0.5 | Medium |

| 8 | Check Safety Features | Monthly | 1 | Critical |

| 9 | Replace Old Components | Annually | 2 | Medium |

| 10 | Document Maintenance Activities | Ongoing | 0.5 | High |

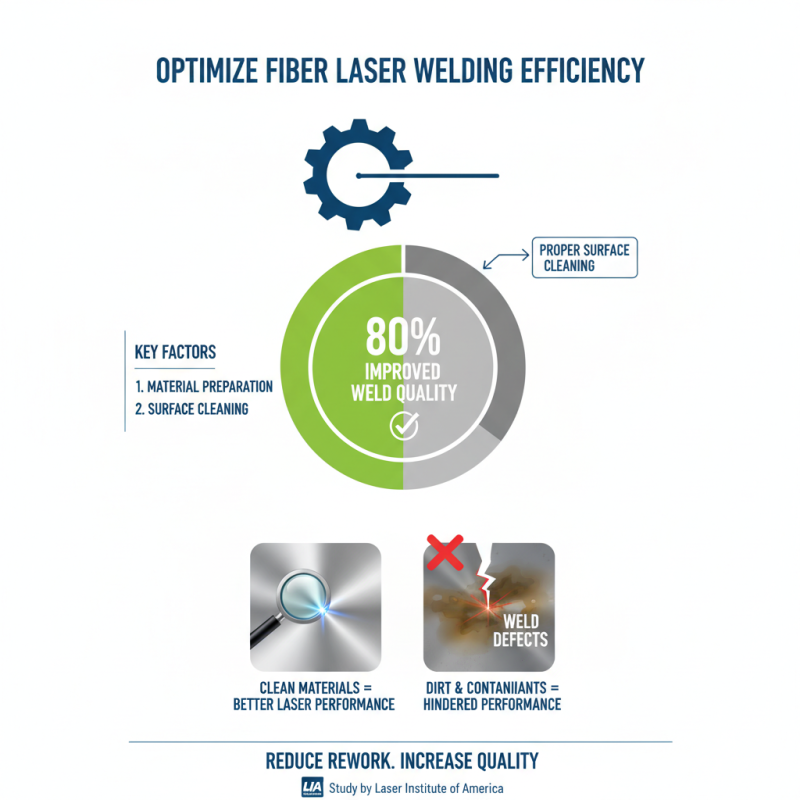

Effective material preparation is vital for optimizing fiber laser welding efficiency. According to a study by the Laser Institute of America, proper surface cleaning can improve weld quality by up to 80%. Dirt, oils, and contaminants hinder laser performance. Even slight imperfections on the surface can lead to defects in welds. Ensuring that materials are clean can significantly reduce the need for rework.

Thickness variations in materials can create challenges too. Data from industry reports indicate that inconsistent thickness can lead to reduced penetration and poor fusion. A uniform thickness allows for better energy transfer, ensuring a more robust weld. Preparing materials through proper cutting techniques and consistent dimensions is essential. Use tools that guarantee precision to minimize discrepancies.

It's also worth noting that the choice of material plays a critical role. Some metals may require specific pre-weld treatments. A report from the American Welding Society highlights that materials like stainless steel need to be passivated before welding to achieve optimal results. Inadequate preparation may lead to brittle welds or corrosion issues over time. Being mindful of these factors can save time and resources, enhancing overall efficiency in fiber laser welding processes.

Training and skill development are crucial for operators of laser welding machines. Proper training can significantly enhance the efficiency of fiber laser welding processes. Experienced operators know the importance of understanding the machine's capabilities. This knowledge can minimize errors and improve overall performance.

Hands-on practice should be a key part of operator training. Theoretical knowledge alone isn't enough. Operators must engage with the equipment regularly. They should take time to observe how different materials react. Learning from mistakes is essential in mastering this technology. Some operators may struggle at first. It's not uncommon to face challenges during the training phase.

Continuous education and refreshers are vital. Technologies change, and techniques evolve. Operators need to stay updated on the latest developments. Workshops and certifications can provide fresh insights. Operators may hesitate to ask for help, but this can hinder progress. Communication within teams can foster a culture of learning. Effective training leads to better outcomes, but operators must embrace their learning journey.