Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the evolving landscape of manufacturing and production, the choice of a suitable Rolling Machine plays a crucial role in operational efficiency and product quality. According to a recent report by the International Machinery Association, the global rolling machine market is projected to grow at a CAGR of 5.3% through 2025, reflecting an increasing demand for versatile and high-performance machinery. The right rolling machine not only enhances productivity but also ensures that manufacturers can meet stringent industry standards.

Experts emphasize the importance of selecting a rolling machine that aligns with specific operational needs. John Anderson, a renowned expert in industrial machinery, states, "The perfect rolling machine is one that balances efficiency, precision, and adaptability to varying production requirements." As manufacturers seek to optimize their operations, understanding the various types of rolling machines available—along with their capabilities and applications—becomes essential. With innovations in technology continually reshaping the industry, making an informed choice is paramount to achieving sustainable growth and maintaining a competitive edge in the market.

Choosing the right rolling machine is more than just a purchase; it’s an investment in the future of production. By understanding the market trends and expert insights, manufacturers can better position themselves to thrive in an ever-competitive environment.

When selecting the right rolling machine for your needs, it's crucial to first understand the specific purposes and functionalities you require. Rolling machines come in various types and sizes, designed to cater to different user preferences and production levels. Ask yourself what types of materials you'll be working with and the volume you anticipate handling. For instance, if your focus is on crafting small batches for personal use, a compact and portable machine might be ideal. On the other hand, for larger operations, investing in a more robust model with advanced features could enhance efficiency and output.

Furthermore, consider the ease of use and maintenance of the rolling machine. A user-friendly interface is essential, especially for beginners. Look for machines that offer adjustable settings to accommodate different rolling techniques and materials.

Additionally, evaluate the machine's cleaning and maintenance requirements, as this will impact its longevity and performance. Prioritizing quality and durability is key, as a well-constructed machine will provide consistent results over time. By thoroughly assessing your needs and the available options, you will be able to choose a rolling machine that enhances your projects and meets your expectations effectively.

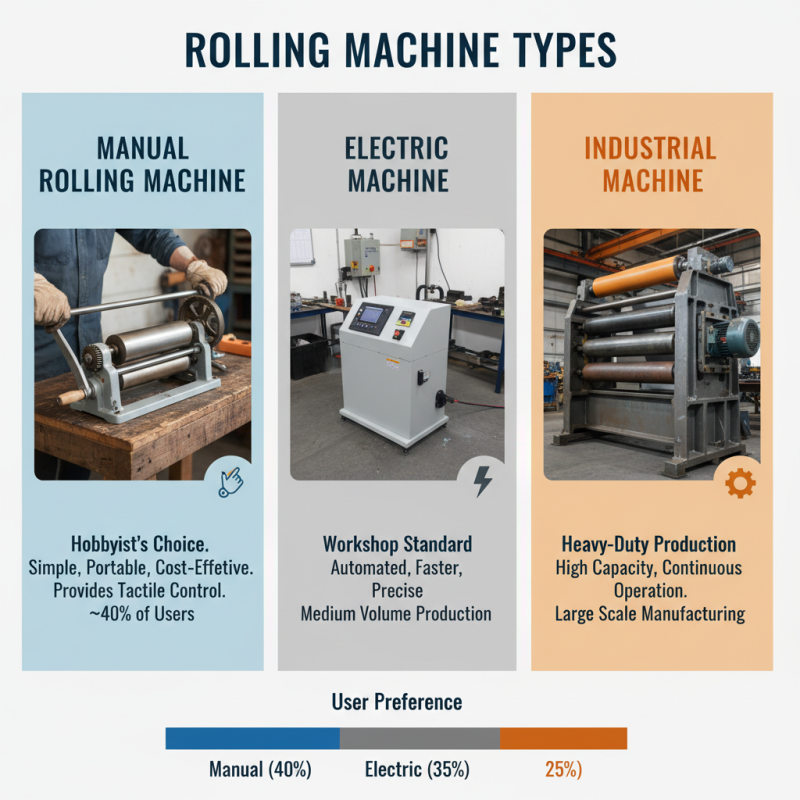

When selecting the right rolling machine, it’s essential to understand the various types available on the market. Rolling machines can generally be categorized into manual, electric, and industrial models. Manual machines are often preferred by hobbyists due to their simplicity and lower cost. According to a recent industry report, approximately 40% of rolling machine users opt for manual versions, appreciating the level of control and the tactile experience they provide.

On the other hand, electric rolling machines cater to higher production needs, offering speed and uniformity that manual options cannot match. Research indicates that about 30% of consumers favor electric machines for their efficiency, particularly in commercial settings. Industrial machines, designed for heavy-duty tasks, account for the remaining 30% of the market. These machines can process large volumes of material and are often equipped with advanced features like automated adjustments for consistency in the rolling process. Understanding these distinctions will help users identify a machine that aligns with their specific operational requirements.

When selecting the right rolling machine for your needs, several key features should be at the forefront of your decision-making process. Firstly, consider the machine's capabilities in terms of the type of materials it can handle. Rolling machines are often designed for specific materials, such as paper, plastics, or metals. Ensuring that the machine can effectively work with the materials you plan to use will significantly influence its performance and your overall satisfaction.

Another crucial aspect to consider is the machine's size and portability. Depending on your workspace and the volume of production, you may opt for a compact model that can be easily moved or stored, or a larger, more robust machine for extensive use. Additionally, assess the ease of operation and maintenance; a user-friendly interface can save time and enhance productivity, while machines that require frequent maintenance can interrupt workflow.

Lastly, think about the added features that may enhance your experience, such as adjustable settings for thickness and speed, digital displays for precision, and safety mechanisms. Evaluating these aspects will help you choose a rolling machine that not only meets your immediate needs but also allows for scalability and versatility in your projects.

When considering the purchase of a rolling machine, budget is a critical aspect that influences both immediate decisions and long-term satisfaction. According to industry reports, the entry-level rolling machines can range from $50 to $150, which can be suitable for casual users or those just starting out. However, as the needs become more specialized, such as for commercial or heavy-use settings, the cost can escalate to well over $1,000. It’s important to weigh the features you require against the initial investment and potential operating costs.

Moreover, aligning your budget with the intended usage is essential. A report by the Equipment Manufacturers Association highlights that businesses investing in higher-quality machines often see a 20% increase in efficiency. This suggests that spending a little more upfront for a durable, efficient machine can lead to significant long-term savings and productivity gains. Therefore, it is crucial to assess not only the purchase price but also the potential return on investment (ROI), maintenance costs, and the expected lifespan of the rolling machine. Balancing these financial considerations will aid in making a more informed choice that meets your specific needs without compromising quality.

When it comes to maintaining a rolling machine, regular care is crucial to ensure its longevity and optimal performance. Start by keeping the machine clean; debris can accumulate in and around the mechanisms, which may lead to malfunctions. After each use, gently wipe down surfaces with a soft cloth and check for any material buildup around the rollers. Additionally, it’s essential to occasionally disassemble parts of the machine for a thorough cleaning, which prevents residue from affecting functionality.

Lubrication is another key aspect of maintenance. Employing the right kind of lubricant can help in reducing friction and wear on moving parts. Follow the manufacturer’s recommendations for the type of lubricant to use and the frequency of application. Regularly inspecting belts, gears, and electrical components for signs of wear or damage also contributes to the overall health of your rolling machine. By staying proactive with these maintenance practices, you can ensure your rolling machine remains in prime condition, ready to meet your needs whenever you require it.