Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In today's highly competitive manufacturing landscape, the demand for precision and efficiency is paramount. The High Precision Laser Cutter has revolutionized industries such as metal fabrication, woodworking, and textiles, allowing for intricate designs and flawless cuts at unprecedented speeds. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from $3.0 billion in 2021 to $4.5 billion by 2026, emphasizing the increasing reliance on laser technology across various sectors. This growth is driven by the rising need for customization and the ability to produce high-quality parts with minimal material waste.

As industries continue to adopt advanced technologies, mastering the use of High Precision Laser Cutters has become essential for operators and manufacturers alike. Understanding the intricacies of laser settings, materials, and maintenance can dramatically affect the quality of the final product. For instance, improper settings can lead to issues such as burn marks or uneven edges, which compromise the integrity of the workpiece. To achieve optimal results, operators must be equipped with expert tips and techniques that ensure perfect cutting every time. In this article, we will explore the top 10 essential tips for maximizing the performance of High Precision Laser Cutters, enabling users to enhance productivity and maintain a competitive edge in the market.

Laser cutting technology has revolutionized various industries, allowing for unparalleled precision in cutting a diverse range of materials, from textiles to metals. Understanding its underlying technology is crucial for optimizing performance and achieving consistently high-quality results. A key aspect of laser cutting is the type of laser used, which can range from CO2 lasers to fiber lasers. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from $3.55 billion in 2020 to $5.90 billion by 2025, underscoring the increasing demand for efficient cutting solutions across sectors.

To achieve optimal precision in laser cutting, several tips can be implemented. First, ensure that your machine is regularly calibrated. This involves checking beam alignment and focal length, which are critical to maintaining cutting accuracy. Data from the Laser Institute of America indicates that improper settings can reduce cutting quality significantly, often resulting in material waste and increased operational costs. Second, maintaining a clean cutting area is essential. Debris or residue on the material can lead to inconsistent results, emphasizing the need for regular maintenance and cleanliness.

Another vital consideration is the selection of the right cutting speed and power settings for the specific material. The thickness and type of material directly influence these settings. Research shows that adjusting these parameters can enhance kerf width, minimize heat-affected zones, and prevent warping. By paying attention to these technical details and implementing best practices, you can ensure precise cuts and improved productivity in your laser cutting operations.

When operating a laser cutter, several essential factors must be considered to ensure precision and efficiency in cutting. One of the foremost considerations is the type of material being used, as different materials respond uniquely to laser cutting. For instance, materials like acrylic and wood generally yield cleaner cuts compared to metals, which may require specific settings for optimal outcomes. According to a report by Research and Markets, the global laser cutting machine market size was valued at approximately $4 billion in 2022, underscoring the growing reliance on accurate laser technology in manufacturing processes.

Another crucial aspect is understanding the laser cutter's settings, including speed, power, and frequency, which significantly influence cutting quality. Incorrect configurations can result in material melting, charring, or incomplete cuts, leading to wastage and increased production costs. A study published in the Journal of Manufacturing Processes found that optimizing these parameters can enhance cutting accuracy by up to 20%. Additionally, environmental factors such as air pressure and humidity can affect the laser beam's performance, making it vital for operators to control their working environment carefully. Ensuring these factors are meticulously managed will contribute significantly to achieving perfect cuts every time.

Maintaining your laser cutter is crucial for achieving high efficiency and precision in your cutting tasks. Regular maintenance not only prolongs the lifespan of the machine but also ensures that it operates at optimal performance. One of the key techniques is to keep the optics clean. Dust and debris can accumulate on the lenses and mirrors, leading to reduced cutting quality and increased energy consumption. A simple routine of checking and cleaning the optics with appropriate materials can prevent these issues.

Another important tip is to regularly check the alignment of your laser cutter. Misalignment can cause uneven cuts and decrease the overall accuracy of your projects. To maintain proper alignment, refer to the machine's specifications and perform calibration checks periodically. This practice will help you achieve consistent results and maintain the cutter’s performance.

Lastly, always monitor the cooling system of your laser cutter. Overheating can lead to failures and decreased cutting effectiveness. Ensure that the cooling system is functioning properly and free of obstructions. Regularly inspect water levels and consider using distilled water to prevent mineral buildup. By following these maintenance techniques, you can keep your laser cutting projects running smoothly and efficiently, ensuring perfect cuts every time.

When working with high precision laser cutters, adjusting key settings based on the material being processed is crucial for achieving perfect cuts. Different materials, such as acrylic, wood, and metal, require specific power, speed, and frequency settings to optimize the cutting process. According to a report from the Laser Institute of America, the correct balance of these parameters can reduce kerf width and minimize heat-affected zones – essential for maintaining the integrity of delicate materials.

For acrylic, a lower speed and high power setting typically yield the best results, allowing for clean edges and reduced melting. Experimenting with the focus of the laser beam is also advisable; a focused beam can create a smaller kerf, thereby enhancing precision.

On the other hand, wood requires a different approach—higher speeds coupled with moderate power can prevent charring and burning, which is often exacerbated by excessive heat.

When cutting metals, a high pulse frequency combined with lower power settings is recommended to avoid excessive warping. Adjusting the air assist pressure can further improve the quality of the cut by blowing away molten material and reducing oxidation.

Each material has its unique sensitivities; therefore, thorough testing and adjustments for specific types can lead to consistently excellent results. By understanding the required settings and making appropriate adjustments, users can maximize the accuracy and efficiency of their laser cutting processes.

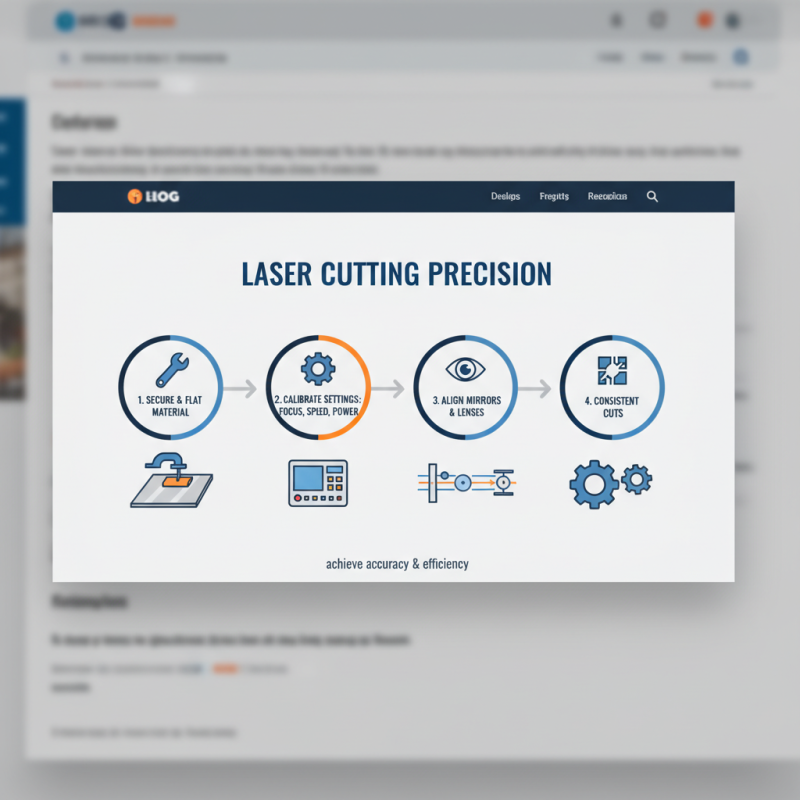

To achieve consistent cutting results with a high precision laser cutter, it is essential to fine-tune several factors that influence the laser cutting process. First, ensuring that the material is properly secured and flat on the cutting bed can drastically reduce vibrations and movement, which can lead to uneven edges. Regularly calibrating the machine for focus, speed, and power settings tailored to the specific material can also enhance the precision of each cut. Checking the alignment of mirrors and lenses helps maintain the beam path, ensuring maximum efficiency and accuracy.

Another crucial element is the selection and maintenance of high-quality optics. Clean lenses and mirrors are vital for optimal laser performance, as any residue can scatter the beam and compromise cutting quality. Additionally, understanding the characteristics of the material, such as its thickness and composition, allows for better adjustments in the cutting strategy. Utilizing proper ventilation and exhaust systems minimizes fumes and debris, further contributing to a clean cutting environment and prolonged equipment life. By integrating these best practices into your workflow, you can achieve the precision and consistency needed for high-quality laser cutting results every time.