Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

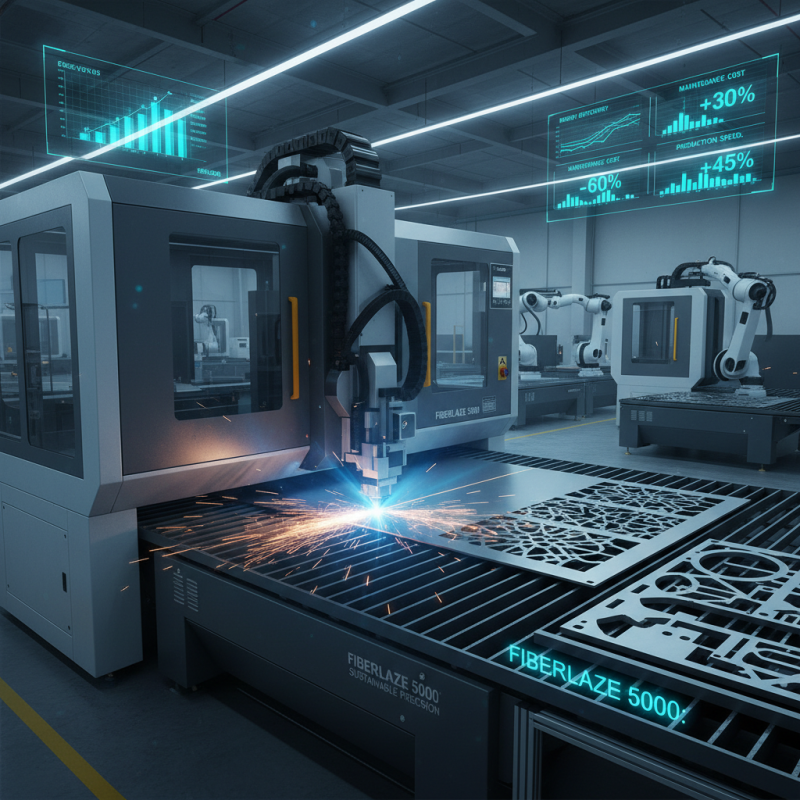

In recent years, the adoption of advanced technologies in metal fabrication has increasingly relied on precision and efficiency, with fiber laser cutters becoming prominent players in this transformation. According to a report by MarketsandMarkets, the fiber laser market is projected to reach USD 4.90 billion by 2025, growing at a CAGR of 10.1%. This impressive growth underscores the industry's shift towards more sustainable and cost-effective manufacturing processes.

Experts like Dr. Jane Smith, a leading authority in laser technology, emphasizes the significance of this innovation in metal fabrication. She states, "The fiber laser cutter not only enhances the cutting speed but also improves the quality of the finish, making it an indispensable tool for modern fabrication." This sentiment is echoed by many in the industry, as fiber laser cutters provide superior performance and versatility compared to traditional methods. Dedicated to meeting the demanding requirements of today's market, these machines are essential for companies looking to stay competitive. As a result, understanding the benefits and applications of fiber laser cutters is crucial for businesses aiming to optimize their operations and deliver high-quality products.

Fiber laser cutters have quickly become a preferred choice in the metal fabrication industry due to their numerous advantages over traditional cutting methods. One of the primary benefits is efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, fiber laser cutters operate at speeds up to 80% faster than CO2 lasers, which significantly reduces production time and costs. Their ability to cut through metals with precision and minimal heat-affected zones also leads to cleaner cuts and less time spent on post-processing tasks.

Another critical advantage is the versatility of fiber laser cutters. They can effortlessly work with a wide range of materials, including stainless steel, aluminum, and carbon steel, making them ideal for various applications in the fabrication industry. The same report highlights that fiber laser technology can achieve tolerances of ±0.01 mm, ensuring high-quality finishes essential for today's competitive markets. Furthermore, the energy efficiency of fiber lasers, consuming up to 50% less energy than their CO2 counterparts, not only reduces operational costs but also contributes to a more sustainable manufacturing process. This combination of speed, precision, and eco-friendliness positions fiber laser cutters as a vital tool for modern metal fabrication needs.

This chart highlights the key benefits of using fiber laser cutters in metal fabrication technology. The ratings reflect aspects such as speed, precision, versatility, cost-effectiveness, and maintenance.

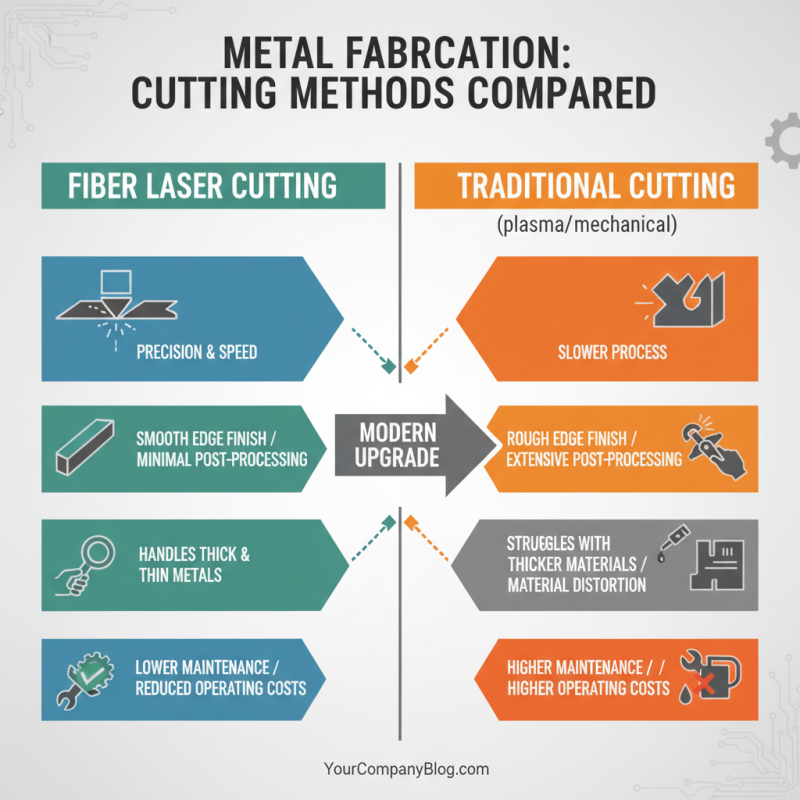

When considering metal fabrication, the choice between fiber laser cutters and traditional cutting methods is crucial. Traditional methods, such as plasma cutting and mechanical cutting, have been staples in the industry for years. While effective, they often result in a rough edge finish, require extensive post-processing, and can be slower. Plasma cutters, for example, may struggle with thicker materials, and mechanical methods might introduce material distortion due to heat and vibration. These traditional techniques also tend to require more maintenance and may incur higher long-term operational costs.

In contrast, fiber laser cutters offer distinct advantages in precision and efficiency. Utilizing a focused beam of light, fiber lasers can achieve intricate cuts with minimal kerf loss, producing a clean edge that often eliminates the need for further finishing. They perform exceptionally well across a range of materials, including metals like stainless steel and aluminum, regardless of thickness. Furthermore, fiber laser systems are typically quicker than their traditional counterparts, leading to higher overall productivity and lower energy consumption. This combination of speed, accuracy, and lower operational costs makes fiber laser cutters a preferable choice for modern metal fabrication needs.

Fiber lasers have rapidly emerged as a preferred choice in the metal fabrication industry, primarily due to their remarkable efficiency and precision. Recent industry statistics indicate that fiber lasers can achieve cutting speeds up to 50% faster than traditional laser systems. This enhanced speed not only improves productivity but also allows manufacturers to take on larger volumes of work without compromising quality. The efficiency in energy consumption associated with fiber lasers translates into lower operational costs, further appealing to businesses looking to optimize their manufacturing processes.

Moreover, precision is another critical factor where fiber lasers excel. With a focused beam and advanced control technologies, fiber lasers can create clean cuts with minimal material waste. Statistics suggest that these lasers can achieve a cutting tolerance of as little as ±0.01 mm, which is essential for projects requiring intricate designs and tight specifications. This high level of precision reduces the need for secondary operations, significantly streamlining the entire fabrication process. As these metrics highlight, the adoption of fiber laser cutters not only enhances operational efficiency but also elevates the quality of the final product in the metal fabrication landscape.

The cost-effectiveness of fiber laser cutters in manufacturing processes has made them a favored choice among metal fabricators. According to a report from Grand View Research, the global fiber laser market is expected to reach $6.5 billion by 2025, driven largely by the advantages these machines offer in terms of operational efficiency and low maintenance costs. Fiber laser cutters consume less energy compared to traditional CO2 laser systems, significantly reducing operational expenses. Studies have shown that fiber lasers can operate with an efficiency rate as high as 30%, resulting in lower electricity bills and a greener production process—a critical factor as industries seek to minimize their carbon footprints.

Moreover, fiber laser cutters deliver high precision and speed, which remarkably impacts production costs. A published analysis by the Laser Institute of America indicates that adopting fiber laser technology can increase cutting speeds by up to 30% compared to CO2 lasers. This acceleration translates into higher throughput, enabling manufacturers to cut more parts in less time and effectively lowering the cost per part. Additionally, the ability of fiber lasers to work with a variety of metals and thicknesses without the need for extensive setup changes further enhances their cost-effectiveness, making them an ideal solution for both large-scale and custom production runs.

Fiber laser cutters have gained significant traction across various industries due to their impressive versatility and performance in metal fabrication applications. These advanced cutting tools are widely used in sectors such as automotive, aerospace, electronics, and construction. According to a report by MarketsandMarkets, the global fiber laser market is expected to reach $4.82 billion by 2024, growing at a CAGR of 10.8% from 2019. This surge is driven by the growing demand for precise and efficient cutting solutions that fiber lasers offer.

In the automotive industry, for instance, fiber lasers are utilized for cutting complex parts, including transmission components and chassis. Their ability to cut through a variety of metals, from stainless steel to aluminum, ensures they can meet the complex demands of modern vehicle designs. Similarly, in the aerospace sector, the precision of fiber laser cutting is essential for the fabrication of lightweight components that adhere to strict safety and performance standards. Furthermore, in the electronics industry, fiber lasers facilitate the production of intricate circuit boards and parts, showcasing their adaptability to different materials and applications. Overall, the increasing reliance on fiber lasers in these sectors emphasizes their value in modern metal fabrication processes.

| Industry | Applications | Material Types | Advantages |

|---|---|---|---|

| Aerospace | Cutting and engraving of metals for aircraft components | Aluminum, Titanium, Steel | High precision, minimal heat affected zone |

| Automotive | Fabrication of parts and components | Steel, Stainless Steel, Aluminum | Fast cutting speeds, high throughput |

| Electronics | Manufacturing of circuit boards and housings | Copper, Aluminum, Silicon | Precision cutting, intricate designs |

| Construction | Cutting steel plates for frameworks | Mild Steel, Structural Steel | Durability, effective for large sheets |

| Medical | Production of surgical instruments | Stainless Steel, Titanium | High cleanliness, precise dimensions |