Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the realm of modern manufacturing, precision and efficiency are paramount. One of the most innovative technologies that have emerged to meet these demands is the Fiber Laser Cutter. Utilizing advanced laser technology, this cutting tool offers unparalleled accuracy and speed, making it invaluable across various industries, from aerospace to automotive. The operating principles of a Fiber Laser Cutter involve the use of a high-powered laser beam, which is generated and delivered through fiber optic cables, allowing for finer cuts and greater detail compared to traditional cutting methods.

The operational mechanism of a Fiber Laser Cutter revolves around the absorption of laser energy by the material being cut, which is then melted or vaporized to produce a clean edge. This technology is not only efficient but also minimizes waste and reduces energy consumption, which is increasingly important in today's eco-conscious manufacturing landscape. With its unique capabilities, the Fiber Laser Cutter stands out as a pivotal tool for achieving high-quality results in metal fabrication and beyond, reshaping the standards of precision cutting in contemporary production environments.

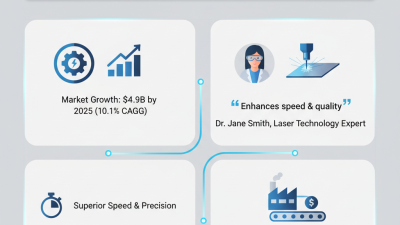

A fiber laser cutter is a high-precision tool that utilizes a solid-state laser to cut through various materials, offering exceptional accuracy and efficiency. The defining feature of a fiber laser is its use of a fiber optic cable as the gain medium, which amplifies light through stimulated emission. This process generates a high-intensity beam capable of cutting through metals such as steel, aluminum, and copper with remarkable speed and precision. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $4.5 billion by 2026, growing at a CAGR of 10.4%. This growth underscores the increasing adoption of fiber laser technology across various industries including manufacturing, automotive, and aerospace.

Fiber laser cutters provide several advantages over traditional cutting methods, including improved cutting speed, reduced waste, and lower operational costs. The technology allows for tighter tolerances, making it ideal for applications that require intricate designs or detailed workpieces. A study by ResearchAndMarkets predicts that the demand for laser cutting machines will rise significantly, driven by the need for high-quality manufacturing processes and customization. The precision offered by fiber lasers not only boosts productivity but also enhances the overall quality of the final product, establishing fiber laser cutters as an indispensable tool in modern fabrication environments.

This bar chart illustrates key performance metrics of fiber laser cutters, including cutting speed, maximum material thickness handled, power consumption, and cost efficiency per millimeter of cut. These metrics highlight the precision and efficiency of fiber laser technology in the manufacturing industry.

Fiber laser cutting technology utilizes a solid-state laser that generates a high-intensity light beam through a series of fiber optics. This laser light is produced by exciting rare-earth elements like ytterbium within the fiber, which allows for efficient energy conversion and high durability. Unlike traditional laser cutting methods, fiber lasers have a much smaller wavelength, resulting in an extremely focused beam that allows for precise cutting capabilities. This feature is particularly advantageous for thin materials, where maintaining integrity and achieving clean edges is crucial.

The operation of a fiber laser cutter involves a combination of optics and motion control systems. The focused laser beam is directed through a lens and meticulously controlled to move across the material. As the laser beam makes contact, it melts or vaporizes the material, often assisted by a gas jet that blows away the molten remnants. The high flexibility of fiber lasers allows them to cut through a variety of metals and industrial materials with remarkable speed, enabling intricate designs and tight tolerances. Furthermore, due to their efficiency and lower power consumption, fiber laser cutters have become increasingly favored in manufacturing processes, enhancing productivity and reducing operational costs.

Fiber laser cutting technology has gained popularity in recent years due to its numerous advantages over traditional cutting methods. One of the key benefits is its exceptional precision. Fiber lasers employ high-density light that can focus on a very fine spot, allowing for intricate cuts and designs. This precision reduces the amount of material waste and the need for extensive post-processing, making it an efficient choice for complex geometries.

Another significant advantage of fiber laser cutting is its speed. Fiber lasers can operate at higher cutting speeds compared to CO2 lasers and mechanical cutting tools. This means that projects can be completed more quickly, increasing productivity and throughput in manufacturing settings. Additionally, fiber lasers have lower operational costs, as they require less maintenance and consume less energy.

Tips for Improving Fiber Laser Cutting Efficiency:

When using fiber laser cutters, consider optimizing parameters such as power settings and cutting speeds based on the material type and thickness. Regular maintenance of the equipment can also enhance its performance and longevity. Moreover, ensuring a clean workspace can prevent contamination, which may affect cutting quality and precision.

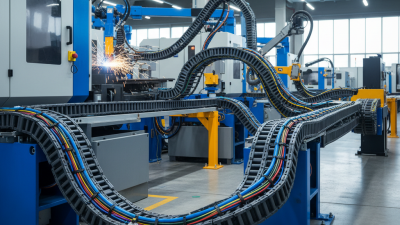

Fiber laser cutters are versatile tools widely utilized across various industries due to their precision and efficiency in cutting complex shapes. In the manufacturing sector, these machines excel in processing metals, including aluminum, steel, and brass. Their ability to produce intricate designs with clean edges makes them invaluable for creating components used in automotive and aerospace applications. Furthermore, fiber laser cutters increase productivity by significantly reducing cutting time, which is crucial for meeting fast-paced production demands.

In the electronics industry, fiber laser cutters are used for the intricate cutting of circuit boards and components. Their precision minimizes material waste and optimizes production efficiency, which is essential as electronic devices become more compact and complex. Additionally, the medical field benefits from fiber laser technology for producing surgical instruments and implants, where precision is critical. The ability of fiber lasers to handle a variety of materials while maintaining accuracy has made them a preferred choice in numerous sectors, demonstrating their significant impact on innovation and efficiency across the board.

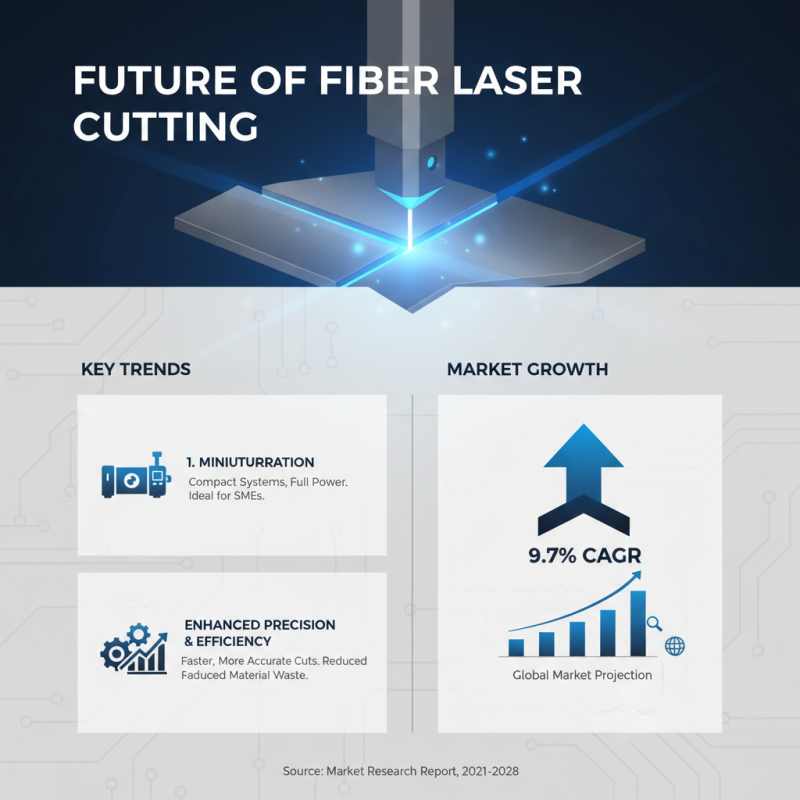

The future of fiber laser cutting technology is being shaped by several key trends that promise to enhance precision and efficiency in manufacturing processes. One major trend is the continued miniaturization of fiber laser systems, which allows for more compact designs without sacrificing power or cutting capabilities. This shift is particularly beneficial for small to medium enterprises that require high precision in tight spaces. According to a recent market research report, the global fiber laser cutting machine market is projected to grow at a CAGR of 9.7% from 2021 to 2028, indicating a robust demand for more efficient cutting technologies.

Another trend is the integration of artificial intelligence (AI) and automation in fiber laser cutting operations. AI algorithms can optimize cutting paths in real-time, enabling machines to adapt quickly to different materials and thicknesses without manual recalibration. A report from a leading industry research firm highlights that advanced automation can reduce production costs by up to 30%, significantly increasing the competitiveness of companies that leverage these technologies. Furthermore, the advent of software-driven solutions allows for enhanced predictive maintenance, minimizing downtime and maximizing output, thereby aligning with the increasing demand for faster delivery times in the manufacturing sector.

As advancements continue, the amalgamation of innovative fiber optics and automation will further improve the capabilities of fiber laser cutting technologies, making them indispensable in precision engineering across various industries. The increasing accessibility of sophisticated fiber laser systems supports a growing trend toward customized manufacturing, meeting specific client needs and driving future developments in the industry.