Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the world of manufacturing, safeguarding equipment and ensuring operational efficiency is paramount. The CNC lathe, a cornerstone of precision machining, faces considerable risks from debris, coolant spills, and operator hazards. An effective means of mitigation is the deployment of CNC Lathe Protective Shells, which not only enhance safety but also improve the longevity of the machinery. According to a 2022 industry report by the National Association of Manufacturers, the use of protective equipment can reduce workplace accidents by up to 30%, underscoring the critical role that such innovations play in modern manufacturing environments.

Renowned CNC machinery expert, Dr. Sarah Thompson, emphasizes the importance of effective protective measures in her recent study, stating, "Implementing CNC Lathe Protective Shells significantly reduces the risk of mechanical failure and operator injury, thereby optimizing overall machine performance." This sentiment resonates with industry leaders who strive for seamless operations and enhanced worker safety. As the demand for precision machining continues to rise, the necessity for robust protective solutions becomes increasingly evident.

The selection of the best CNC Lathe Protective Shells is therefore not merely a matter of compliance but a strategic decision that can propel manufacturers towards greater safety and efficiency. By investing in quality protective solutions, businesses can safeguard their most valuable assets – their machines and their workforce – while maintaining a competitive edge in an ever-evolving marketplace.

In the world of manufacturing, the safety and efficiency of machinery are paramount, especially when it comes to CNC lathes. Protective shells serve a critical role in safeguarding both the equipment and the operators. These shells are designed to absorb and deflect potential hazards, such as flying debris and coolant splashes, which can occur during the machining process. By providing a robust barrier, they help prevent accidents that could lead to injuries, ensuring a safer work environment.

Moreover, using high-quality protective shells can enhance the efficiency of CNC lathes. By keeping contaminants such as dust and chips away from vital machine components, they help maintain precise operation and reduce downtime. This protection contributes to a longer lifespan for the machinery, minimizing the need for costly repairs and maintenance. Additionally, with improved safety and operational efficiency, manufacturers can focus on optimizing their output and meeting production demands, ultimately benefiting the overall productivity of the facility.

When it comes to ensuring optimal safety and efficiency for CNC lathes, the type of protective shell used plays a crucial role. There are several materials and design options available that cater to the specific needs of different machining environments. Common materials include polycarbonate, metal alloys, and specialized plastics. Polycarbonate is favored for its durability and impact resistance, making it ideal for high-speed operations where debris might pose a risk. Metal alloy shells provide robust protection against heavy impacts and can shield sensitive components from external hazards, while plastics often offer a lightweight alternative that maintains adequate protection without adding unnecessary bulk.

In terms of design, protective shells can vary substantially to accommodate the unique requirements of different CNC applications. Some shells feature transparent panels that allow operators to monitor the machining process without compromising safety, while others may incorporate adjustable openings for ventilation or access to the machine controls. Moreover, customizable designs can provide tailored protection solutions, such as tailored shapes that snugly fit over machine parts or modular systems that allow for easy assembly and disassembly. By selecting the right material and design, manufacturers can significantly enhance the operational safety and efficiency of their CNC lathes.

The importance of protective shells for CNC lathes cannot be understated, particularly when it comes to enhancing safety in machining environments. Studies have shown that machines equipped with proper protective covers face a significantly reduced risk of accidents. For instance, a survey revealed that about 70% of injuries in machining facilities occurred due to flying debris and accidental contact with moving parts, which could potentially be mitigated by employing effective protective shells. These statistics highlight the critical role that protective shells play in safeguarding operators and prolonging machine life.

To further enhance safety and efficiency, consider these tips: First, ensure that the protective covers are made from durable materials that can withstand the rigors of machining, including sharp debris and high-speed projectiles. Regular maintenance checks are essential; inspect the integrity of the shells and replace them at the first sign of wear. Additionally, training operators on the proper usage and limitations of these protective shells can greatly reduce the likelihood of accidents. Remember, a well-informed team combined with adequate safety measures lays the foundation for a safer work environment.

Protective shells for CNC lathes are essential not only for safeguarding the machine itself but also for enhancing operational efficiency. According to a report by the National Institute of Standards and Technology, approximately 60% of machine downtime in manufacturing is attributed to equipment failure, often due to inadequate protection from debris and coolant. By implementing robust protective shells, manufacturers can significantly reduce wear and tear on their equipment, thereby extending its lifespan and maximizing utilization rates.

Moreover, effective protective shells can improve the working environment by containing noise and vapors that typically result from machining processes. Research conducted by the American Society of Precision Engineering revealed that reducing noise levels in manufacturing settings by just 10 dB can lead to a measurable increase in worker productivity, along with fewer distractions. Additionally, protective shells help to maintain consistent temperature control, which is crucial for precision machining. Temperature fluctuations can lead to dimensional inaccuracies and poor surface finishes, ultimately affecting the quality of the output and increasing waste. By ensuring that CNC lathes are well-protected, manufacturers not only enhance their operational efficiency but also uphold high standards of product quality, driving overall business success.

| Model | Material | Weight (lbs) | Dimensions (inches) | Features | Price ($) |

|---|---|---|---|---|---|

| CNC Shell A | Steel | 45 | 60 x 30 x 40 | Corrosion-resistant, Easy to install | 1200 |

| CNC Shell B | Aluminum | 35 | 55 x 28 x 35 | Lightweight, High thermal conductivity | 950 |

| CNC Shell C | Polycarbonate | 20 | 50 x 25 x 30 | Impact-resistant, Transparent | 700 |

| CNC Shell D | Fiberglass | 50 | 62 x 32 x 42 | Durable, Weather-resistant | 1300 |

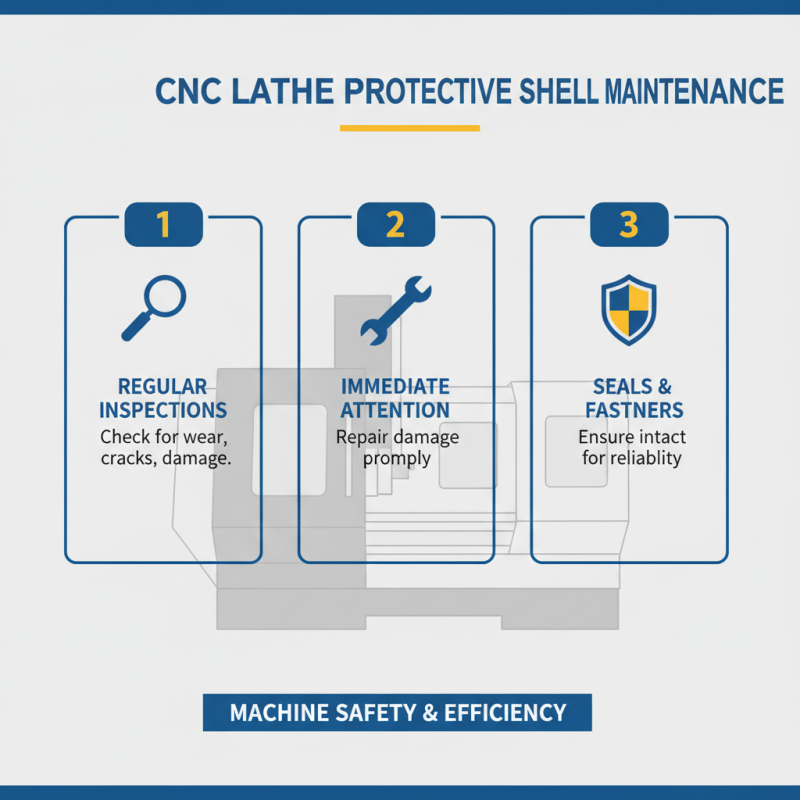

Maintaining the integrity and functionality of CNC lathe protective shells is crucial for ensuring both machine safety and efficiency. Regular inspections should be a fundamental part of maintenance routines. Operators should look for signs of wear, cracks, or other damage that could compromise the protective shell’s effectiveness. Immediate attention to any damage not only prolongs the life of the shell but also protects the lathe itself from contaminants and harmful debris. Additionally, ensuring that seals and fasteners are intact can significantly enhance the overall reliability of the protective shell.

Cleaning is another vital aspect of maintaining CNC lathe protective shells. Operators should use appropriate methods and materials that do not cause harm to the shell's surface. Dust, chips, and coolant residues can accumulate over time, leading to corrosion or other issues if not addressed. A scheduled cleaning regimen coupled with the use of protective coatings can help maintain the shell’s pristine condition. Moreover, educating staff on best practices for handling and maintaining these shells will foster a culture of care and responsibility, ultimately contributing to the longevity and performance of the machinery. Implementing these best practices ensures the protective shells serve their purpose effectively, safeguarding the lathe and promoting efficient operation.