Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving world of manufacturing, the precision and longevity of machinery are paramount. Among various equipment essential for high-quality production, CNC lathes play a critical role in shaping materials with exceptional accuracy. To enhance the durability and performance of these machines, the use of protective coverings has become increasingly important. This is where the significance of CNC Lathe Metal Protective Covers comes into play.

As manufacturers look ahead to 2025, investing in top-notch protective covers can significantly reduce maintenance costs and extents the operational lifespan of CNC lathes. These covers are designed to shield vital components from environmental factors such as dust, moisture, and mechanical wear, ensuring that machines run smoothly and efficiently. In an industry where precision engineering and reliable uptime are crucial, understanding the benefits of CNC Lathe Metal Protective Covers is essential for any business looking to optimize their production capabilities.

This article will explore the key features and advantages of the best CNC Lathe Metal Protective Covers available in 2025, helping manufacturers make informed decisions to preserve their investments in cutting-edge technology. By prioritizing durability and protection, businesses can maintain their competitive edge in a demanding market.

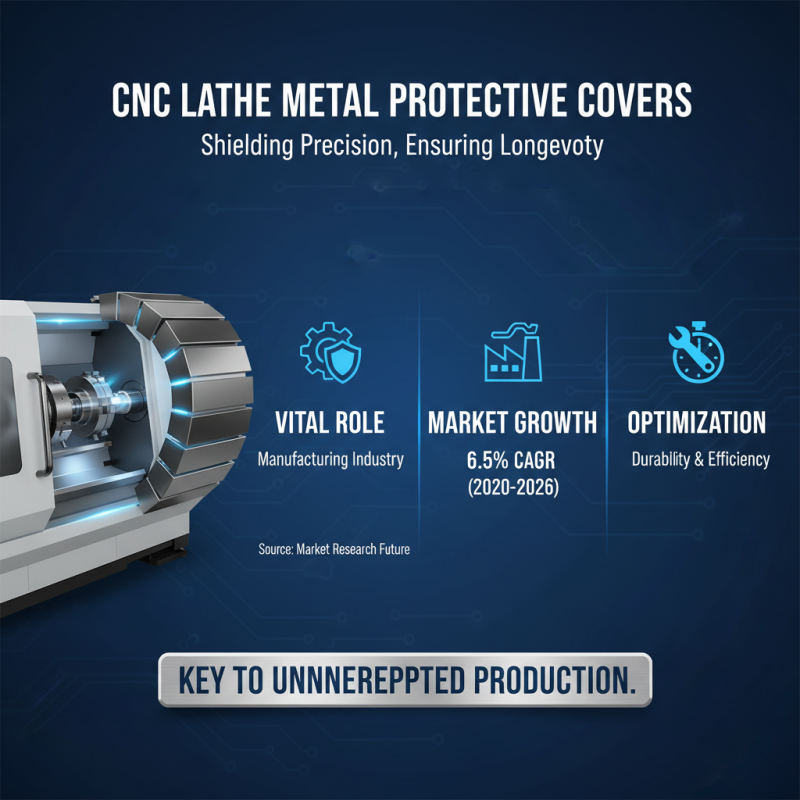

CNC lathe machines are vital in the manufacturing industry, contributing significantly to precision machining processes. One critical yet often overlooked component in maintaining the longevity and efficiency of these machines is the protective covers made from durable metal. Understanding the importance of CNC lathe metal protective covers is essential for manufacturers aiming to optimize their operations. According to a report from Market Research Future, the global CNC machine market is projected to grow at a CAGR of 6.5% from 2020 to 2026. This exponential growth amplifies the necessity for protective measures that ensure the equipment's durability and consistent performance.

Effective protective covers shield CNC lathes from various environmental factors, including dust, moisture, and debris, which can lead to premature wear and tear. A study by the National Institute of Standards and Technology highlights that proper maintenance protocols, which include using high-quality protective covers, can reduce machinery downtime by up to 30%. This is crucial for manufacturers looking to enhance productivity and reduce operational costs. Furthermore, metal covers are specifically designed to withstand impacts and maintain structural integrity, providing an essential layer of defense against accidental damage and extending the lifespan of the machinery.

The increasing demand for precision and efficiency in manufacturing processes mandates a proactive approach to machine maintenance. With advancements in materials and manufacturing technologies, investing in high-quality CNC lathe metal protective covers not only safeguards the equipment but also contributes to overall operational efficiency and cost-effectiveness. By ensuring that CNC machines are well-protected, manufacturers can achieve sustained longevity and reliability, ultimately leading to increased profitability in a competitive landscape.

When selecting protective covers for CNC lathes, durability should be a top priority. A study by the International Journal of Advanced Manufacturing Technology highlights that the longevity of protective materials can significantly influence the maintenance costs of CNC machinery. Covers made from high-density polyethylene (HDPE) or reinforced PVC significantly outperform traditional materials in terms of resistance to wear, chemicals, and UV light. These materials can enhance the lifespan of both the machine and the protective cover, ultimately reducing downtime and associated costs by up to 20%.

Key features to consider include water and dust resistance, which are critical for maintaining the precision and functionality of CNC lathes. According to a report by the American Society of Mechanical Engineers, CNC machines exposed to adverse environmental conditions can experience an increase in operational failures by 15% to 30%. Opting for covers with sealed seams and adjustable closures ensures maximum protection against contaminants. Additionally, lightweight yet strong materials facilitate easy installation and removal, thereby increasing efficiency in workflow processes. Understanding these factors will empower operators to make well-informed choices that enhance the durability and performance of their CNC lathes.

| Material | Thickness (mm) | Temperature Resistance (°C) | Water Resistance | UV Protection | Weight (kg) | Price ($) |

|---|---|---|---|---|---|---|

| Steel | 2.5 | 300 | Yes | Yes | 5.0 | 150 |

| Aluminum | 3.0 | 250 | Yes | No | 4.2 | 120 |

| Polycarbonate | 2.0 | 100 | Yes | Yes | 2.5 | 80 |

| Stainless Steel | 3.5 | 400 | Yes | No | 6.0 | 200 |

| PVC | 1.5 | 80 | Yes | Yes | 1.5 | 50 |

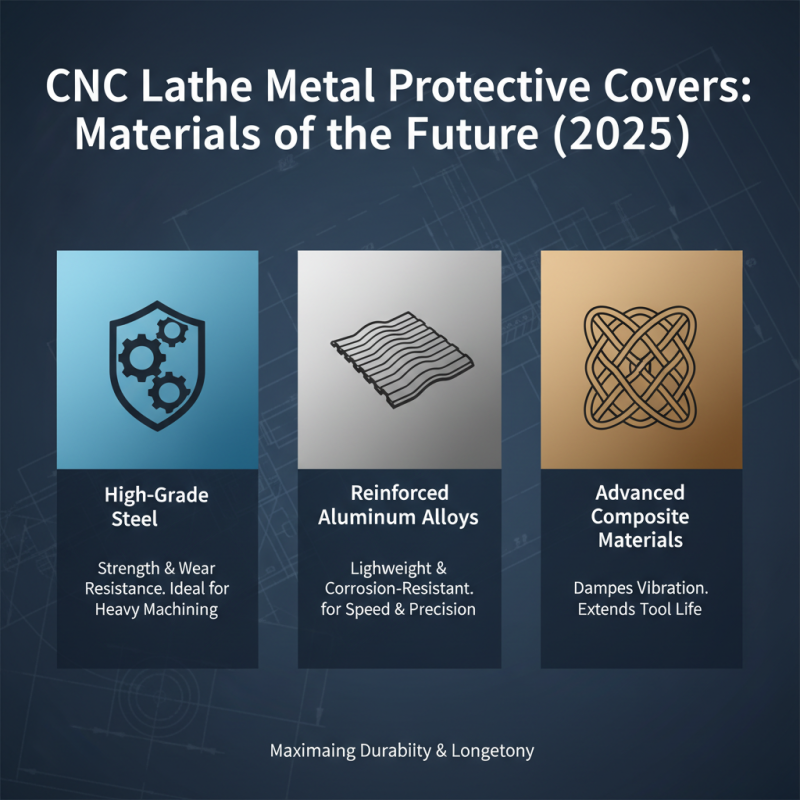

When it comes to CNC lathe metal protective covers, the choice of materials plays a critical role in ensuring maximum durability and longevity. In 2025, several key materials stand out for their exceptional properties. First and foremost, high-grade steel is commonly used due to its impressive strength and resistance to wear. The robustness of steel makes it ideal for environments where heavy metal machining occurs, as it can withstand impact and abrasion while maintaining structural integrity.

Additionally, advanced polymers are gaining traction as viable options for CNC lathe protective covers. These synthetic materials are often lightweight yet incredibly durable, making them suitable for applications that require significant flexibility without compromising strength. Materials such as polyethylene and polycarbonate offer excellent protection against chemicals and environmental factors, thus enhancing the lifespan of the covers while also providing ease of handling and installation.

Lastly, composites that combine the benefits of both metals and polymers are becoming increasingly popular. By merging the durability of metal with the lightweight and corrosion-resistant properties of polymers, manufacturers can create covers that meet the demanding needs of modern CNC machinery. This innovative approach not only enhances performance but also contributes to cost efficiency in production, making composite materials a key focus for protective cover development in the coming years.

When evaluating CNC lathe metal protective covers, several factors come into play to determine the best options for durability and reliability in industrial settings. Different brands offer a variety of materials that exhibit varying degrees of resistance to abrasions, impacts, and corrosive substances. For instance, some covers are designed with reinforced elements to withstand high-velocity impacts, thereby extending their lifespan in demanding environments. The choice of material often correlates with the intended application of the CNC lathe, as some industries may require covers that can tolerate extreme temperatures or chemical exposure.

In addition to material composition, the design and fit of protective covers greatly impact their effectiveness. Many leading brands focus on creating custom-fit solutions that ensure comprehensive protection without hindering the machine's operation. Features such as easy installation and maintenance, as well as flexibility to accommodate different lathe designs, are essential considerations. Moreover, user feedback and performance metrics play a vital role in comparative analyses, enabling potential buyers to assess the long-term value of these protective covers in maintaining the integrity and functionality of their CNC lathes.

To ensure the longevity of CNC lathe metal protective covers, regular maintenance is essential. Start by routinely inspecting the covers for any signs of wear and tear. Check for scratches, dents, or rust that might compromise their integrity. Cleaning the covers with a non-abrasive cloth and appropriate cleaning agents will help remove debris and prevent buildup that can lead to corrosion or damage.

In addition to regular inspections, applying protective coatings can significantly extend the lifespan of the covers. These coatings act as barriers against moisture and chemicals, which are common enemies of metal surfaces. It's also important to manage the environmental conditions where the CNC equipment is housed. Maintaining a stable temperature and humidity level can reduce the risk of corrosion and deterioration. Following these maintenance tips will ensure that your CNC protective covers remain effective and durable for years to come.