Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the manufacturing industry, the importance of protecting machinery cannot be overstated, particularly when it comes to a crucial component like the CNC lathe. A CNC Lathe Metal Protective Cover serves as a vital safeguard for such machinery, ensuring its longevity and preserving its operational efficiency. According to industry expert Dr. James Holloway, a renowned specialist in CNC technology, "Investing in a CNC Lathe Metal Protective Cover is not just about protection; it's about optimizing performance and minimizing downtime."

These protective covers are designed to shield CNC lathes from environmental hazards such as dust, debris, and moisture, which can significantly impact the machine's functionality. By implementing a CNC Lathe Metal Protective Cover, manufacturers can reduce the risk of costly repairs and enhance the overall productivity of their operations. The significance of this investment extends beyond mere protection, highlighting a commitment to quality and operational excellence.

In conclusion, the adoption of a CNC Lathe Metal Protective Cover is essential for any business looking to maintain high standards of equipment care and efficiency. With experts like Dr. Holloway pointing towards the critical role these covers play, it becomes evident that understanding and prioritizing this aspect of machinery maintenance is key to achieving long-term success in the competitive landscape of manufacturing.

A CNC lathe metal protective cover is an essential accessory designed to safeguard both the machine and the operator in industrial settings. These covers provide a barrier against metal shavings, coolant, and other debris generated during the machining process. According to a recent industry report by MetaMachinery Insights, CNC machine downtime caused by maintenance issues, often related to debris accumulation, can account for up to 15% of operational costs. Implementing effective protective covers can mitigate these costs significantly, enhancing productivity and ensuring a safer work environment.

The materials used in CNC lathe metal protective covers vary, but common options include durable metals and impact-resistant plastics that withstand the rigors of machining operations. These covers are designed not only to protect the integrity of the CNC machine but also to minimize potential hazards for operators. Research published in the Journal of Manufacturing Safety underscores that proper shielding can reduce the risk of accidents by up to 30%, highlighting the importance of incorporating protective elements in CNC setups. Overall, a well-designed metal protective cover is vital for maintaining machine performance and ensuring workplace safety.

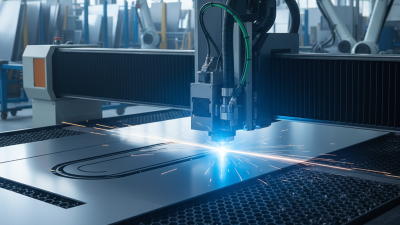

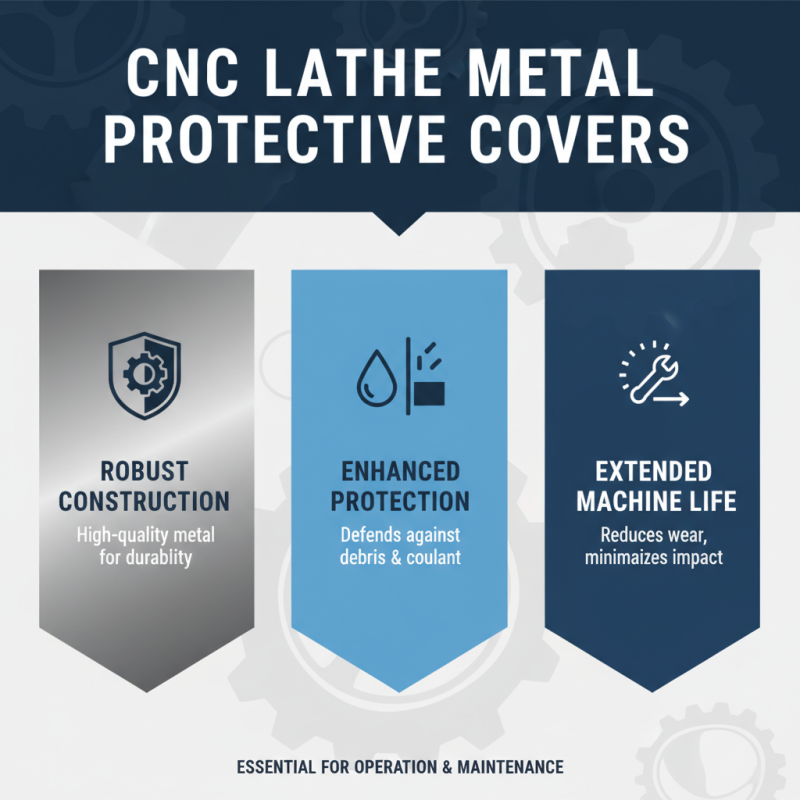

CNC lathe metal protective covers are essential components used to safeguard machines during operation and maintenance. One of the key features of these protective covers is their robust construction, typically made from high-quality metal that ensures durability and resilience against wear and tear. This heavy-duty material not only provides physical protection from debris and coolant but also helps to reduce the impact of harsh working conditions, extending the life of the CNC lathe.

Another significant attribute of CNC lathe metal protective covers is their precision fit. These covers are designed to closely match the dimensions of the lathe machine, effectively preventing dust, chips, and other contaminants from infiltrating critical areas. The tailored design also enhances operational safety by reducing the risk of accidental contact with moving parts. Additionally, many covers come equipped with features like easy-access openings for maintenance, which streamline servicing without compromising protective effectiveness. These aspects collectively contribute to improved machine performance, reduced downtime, and increased efficiency in manufacturing processes.

A CNC lathe metal protective cover serves as a vital accessory to ensure the longevity and functionality of the machinery. One of the primary benefits of using a protective cover is its ability to shield the CNC lathe from dust, debris, and contaminants that could accumulate during the machining process. This protective barrier not only minimizes the wear and tear on delicate components but also contributes to maintaining a clean working environment, which is essential for precision engineering.

Additionally, a protective cover can help mitigate the risks of accidental damage. CNC lathes are often situated in busy workshops where unforeseen incidents can occur, such as accidental spills or equipment collisions. By using a metal protective cover, operators can significantly reduce the likelihood of damage to expensive components, thereby saving costs on repairs and downtime. Furthermore, these covers can be designed to withstand harsh working conditions, ensuring that the lathe remains operable and efficient for an extended period. Overall, investing in a CNC lathe protective cover is a smart decision for enhancing productivity and safeguarding machinery.

CNC lathe metal protective covers play a crucial role in safeguarding machinery from various environmental and operational hazards. These covers are designed to protect the internal components of CNC lathes from dust, debris, and coolant, which can cause wear and tear. Not only do they enhance the longevity of the equipment, but they also promote safety in the workplace by reducing the risk of accidents associated with exposed moving parts.

When it comes to materials used for CNC lathe protective covers, several options are prevalent in the industry. Common materials include metal, such as stainless steel or aluminum, which provide high durability and resistance to corrosion. Additionally, engineered plastics like polycarbonate and polyethylene are increasingly being used due to their lightweight properties and ability to withstand impact.

According to industry reports, the demand for advanced materials in protective covers is projected to grow significantly, with a 7% annual increase expected in the next five years as manufacturers prioritize both performance and safety. These materials not only offer robust physical protection but are also engineered to withstand the specific conditions present in machining environments, ensuring reliability over time.

Maintaining CNC lathe metal protective covers is essential for ensuring the longevity and efficiency of your equipment. These covers are designed to shield the internal components of the CNC lathe from dust, debris, and other contaminants, which can lead to wear and tear. To maximize their effectiveness, regular inspection and cleaning are critical. Users should check for any signs of damage or corrosion, as these could compromise the protective function of the cover. A simple wipe-down with a suitable cleaner can help remove any accumulated grime, keeping the lathe in optimal working condition.

In addition to routine inspections, lubrication plays a key role in maintenance. Proper lubrication of hinges and moving parts of the protective cover can ensure smooth operation and prevent mechanical failure. It's also important to monitor the fit of the cover; a loose cover can expose sensitive components to contaminants, while a tight fit can inhibit its function. Always follow guidelines for maintenance based on the specific conditions in which the CNC lathe operates. By implementing these maintenance tips, users can extend the lifespan of both the protective cover and the CNC lathe itself, resulting in more efficient production processes.