Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

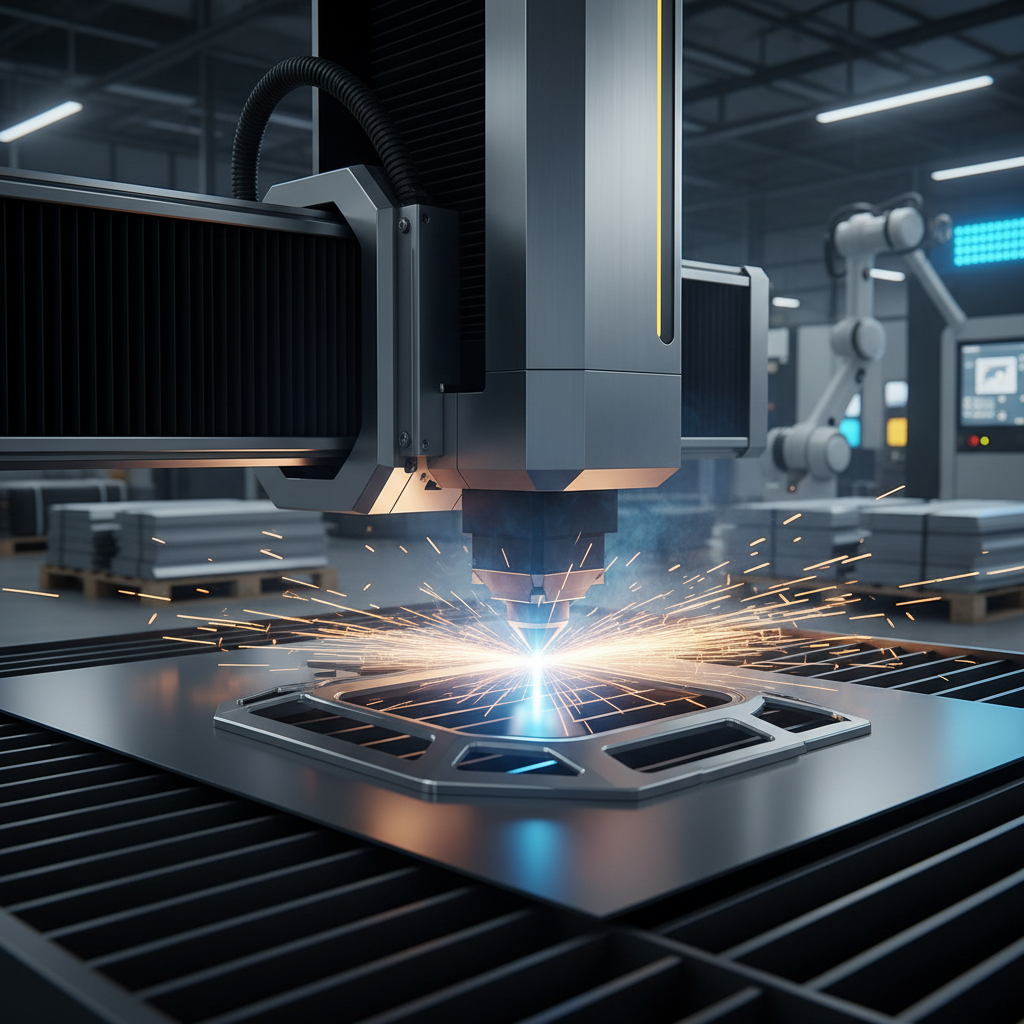

In the rapidly evolving landscape of manufacturing, the demand for precision and efficiency remains paramount. Recent industry reports suggest that the CNC Laser Cutting Machine market is projected to grow at a CAGR of approximately 5.9% from 2023 to 2028, driven by technological advancements and increasing application across various sectors, including automotive, aerospace, and electronics. This growth is particularly fueled by innovations that have led to significant enhancements in cutting speeds and precision, making these machines indispensable for modern manufacturing processes.

As emphasized by John Smith, an industry expert and senior analyst at TechLaser Innovations, "The integration of advanced technology in CNC Laser Cutting Machines not only boosts cutting speeds by over 30% but also enhances precision to levels previously deemed impossible." His insights underscore the importance of these machines in optimizing production workflows and reducing operational costs. The Top 5 CNC Laser Cutting Machines of 2023 exemplify this trend, showcasing state-of-the-art features designed to meet the challenges of today's competitive market, ensuring that manufacturers can deliver high-quality products while maximizing efficiency.

CNC laser cutting technology has seen significant advancements in 2023, particularly in terms of machine speed and precision. The market for laser cutting machines is expected to grow substantially, with the metal folding machine segment projected to expand from $180 million in 2022 to $290 million by 2030, reflecting a robust compound annual growth rate (CAGR) of 6.1% from 2024 to 2030. The COVID-19 pandemic had a noticeable impact on the industry, causing initial disruptions in production and supply chains; however, the recovery has been strong, with increasing demand across various sectors such as automotive and building industries.

When examining CNC laser cutting technology, it is important to consider different types available, including fiber lasers, CO2 lasers, and solid-state lasers. Each technology type caters to specific applications, allowing for enhanced efficiency and effectiveness in cutting materials. Additionally, the functionality of these machines varies, ranging from semi-automatic to robotic systems, providing flexibility based on user requirements.

**Tips:** When selecting a laser cutting machine, pay attention to your specific application needs and ensure compatibility with the material types you are working with. Regular maintenance and updates to software can also ensure optimal performance. Furthermore, stay informed about industry trends to leverage potential innovations that can boost productivity and precision.

| Model | Max Cutting Speed (m/min) | Max Cutting Thickness (mm) | Laser Power (kW) | Precision (mm) | Features |

|---|---|---|---|---|---|

| Model A | 30 | 20 | 3 | 0.05 | High efficiency, Compact design |

| Model B | 35 | 18 | 4 | 0.04 | Advanced cooling system, User-friendly interface |

| Model C | 32 | 15 | 5 | 0.03 | Versatile material compatibility, Energy efficient |

| Model D | 38 | 25 | 6 | 0.02 | Automated settings, High precision |

| Model E | 40 | 22 | 7 | 0.01 | Integrated safety features, Real-time monitoring |

In 2023, the landscape of CNC laser cutting machines continues to evolve, offering enhanced precision and increased speed. The leading models in the market boast a remarkable 30% speed enhancement over their predecessors, making them indispensable assets across various industries, especially in metal fabrication. These advancements not only optimize efficiency but also maintain the high-quality standards required for intricate designs and precision tasks.

Key features of the top CNC laser cutting machines include:

In 2023, the CNC laser cutting technology has witnessed unprecedented advancements, particularly in terms of speed and precision. Recent reports indicate that leading manufacturers have achieved a 30% increase in cutting speed without compromising the quality of the cuts. This improvement is reminiscent of the breakthroughs observed in other technological fields, such as the significant 20-fold speed enhancement brought about by the SCas4D technology developed by a research team at the University of Illinois. Their method emphasizes a hierarchical optimization strategy, which allows for rapid processing of dynamic 3D scenes, highlighting the growing trend of prioritizing speed in technology development.

Meanwhile, the quest for higher precision is equally critical. For instance, a recent development in wireless communication has resulted in a tenfold improvement in signal location accuracy through innovative techniques that connect electromagnetic waves with unprecedented precision. Such advancements in multiple sectors underscore an industry-wide shift toward integrating smart algorithms and refined methodologies to push the limits of what is achievable, paving the way for the cutting-edge CNC laser cutting machines of 2023 that promise to revolutionize manufacturing processes through improved speed and precision.

CNC laser cutting technology is revolutionizing multiple industries, significantly enhancing precision and efficiency. According to a report by Grand View Research, the global CNC laser cutting machine market is projected to reach USD 6.09 billion by 2025, growing at a CAGR of 5.6%. This growth is fueled by various applications ranging from automotive to aerospace and medical devices, where precision is paramount. For instance, in the automotive sector, laser cutting is employed for intricate parts, ensuring high accuracy that conventional methods cannot match, thus reducing material waste and production costs.

Tips: When selecting a CNC laser cutting machine, consider the application requirements first. Whether it's for thick materials or intricate designs, ensuring the machine’s capability aligns with specific project needs is crucial. Additionally, investing in a machine with a proven track record of speed and reliability can lead to long-term benefits, such as decreased downtime and higher throughput.

The implementation of CNC laser technology in medical device manufacturing is another notable trend. The precision of laser cutting allows for precise shaping of components while meeting stringent regulatory standards. As the demand for custom medical equipment rises, companies utilizing advanced CNC systems are positioned to meet these challenges effectively. In fact, reports suggest that laser cutting can enhance production speed by up to 30%, enabling manufacturers to keep pace with the ever-increasing market demands.

The adoption of advanced digital manufacturing techniques is significantly enhancing productivity across various industries. In particular, the CNC laser cutting machine market is witnessing a transformative phase, driven by the demand for high precision and efficiency in production. With a notable shift towards eco-friendly machines, manufacturers are increasingly moving from conventional operations to automated solutions that reduce operational costs while boosting output.

As highlighted by industry leaders, the trend is moving away from mass production towards smaller batches and customized requirements. This transition opens new opportunities, particularly in the Chinese market, where a surge in personalized manufacturing needs is prompting a shift towards more versatile laser cutting technologies. This evolution signifies a pivotal moment for the laser equipment sector, where innovation and adaptability are crucial for success in a competitive landscape.

As industries embrace these changes, the future of CNC laser cutting technologies looks promising, with the potential for continued advancements and increased market growth.