Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

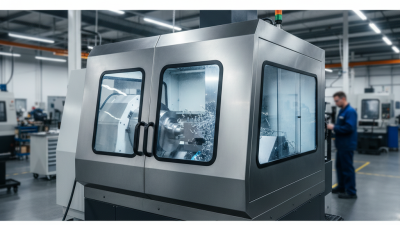

Selecting the appropriate CNC Machining Center is crucial for optimizing production efficiency and quality in today's competitive manufacturing landscape. According to the latest market research report by Smith & Associates, the global CNC machining market is projected to reach $100 billion by 2025, with increasing demand for precision engineering and automation. This rapid growth underscores the importance of choosing the right machining center to align with particular manufacturing needs and objectives.

Industry expert Dr. Emily Tran, a leading authority in CNC technology, emphasizes the significance of this decision: "The right CNC Machining Center can not only enhance productivity but also significantly reduce operational costs." As manufacturers strive to incorporate advanced technologies, understanding the various types of CNC machining centers, their functionalities, and adaptability to specific production processes becomes imperative. By making informed choices, businesses can position themselves to respond effectively to market demands while achieving long-term success in their manufacturing endeavors.

CNC machining centers are essential tools in modern manufacturing, offering precision and versatility across various industries. These machines come in different types, each designed to fulfill specific functions and cater to diverse manufacturing needs. For instance, vertical machining centers (VMCs) are widely used for their ability to perform multiple operations like drilling, milling, and tapping in a single setup. Their upright design allows for easy loading and unloading of materials, making them ideal for jobs requiring quick turnaround times.

On the other hand, horizontal machining centers (HMCs) offer enhanced efficiency for larger and heavier workpieces. With their rotating spindle oriented horizontally, these machines facilitate better chip removal and provide improved accessibility to the workpiece during machining. This design reduces tool wear and increases overall productivity. Additionally, CNC lathes, while not traditional machining centers, are also integral to the process, specializing in creating cylindrical parts by rotating the workpiece against a stationary cutting tool. Understanding these different types and functions of CNC machining centers is crucial for manufacturers looking to select the right equipment that aligns with their specific operational requirements and production goals.

When selecting a CNC machining center, several key factors come into play that can significantly influence your manufacturing processes. The first consideration should be the type of materials you'll be working with. Different machining centers have varying capabilities when it comes to handling metals, plastics, and composites. Understanding the material properties and selecting a machine that can efficiently cut, mill, or drill through those specific materials is essential for optimal performance. Additionally, consider the tolerances required for your projects; a machine that offers higher precision may be necessary for intricate designs.

Another vital factor is the size and configuration of the machining center. Assess the dimensions of the parts you intend to manufacture and ensure the machine has the appropriate working envelope. Furthermore, the layout of the shop floor should be taken into account, as some machining centers may require more space and specific configurations for optimal workflow. Lastly, evaluate the machine’s speed and productivity features, as these can directly impact your production rates. A balance of these considerations will help you choose a CNC machining center that not only meets your current requirements but also supports your future manufacturing goals effectively.

When evaluating the specifications and performance of CNC machines, several critical factors should be considered. First, the type of materials you will be machining plays a significant role in determining the suitable CNC center. Different machines vary in their capabilities to handle various materials, whether they are metals, plastics, or composites. Look for specifications such as spindle speed and torque, which can significantly affect machining efficiency and surface finish. A machine with high spindle speed is conducive for intricate designs and finer details, while a higher torque is essential for heavy-duty tasks.

Additionally, the machine's travel distances and dimensions are crucial for accommodating the size of the workpieces. A CNC machining center should not only fit your current projects but also future needs, as the flexibility to handle larger or different workpieces can save time and resources in the long run. Furthermore, consider the machine's control system and its user interface, as a more intuitive system can lead to improved operator efficiency and fewer errors. Lastly, machine accuracy and repeatability specifications are vital for ensuring that production meets required tolerances and quality standards, which ultimately impacts the success of your manufacturing operations.

When considering the investment in a CNC machining center,

budget and cost considerations play a critical role in the decision-making process.

First, it is essential to understand the initial costs associated with purchasing a CNC machine.

This includes not only the purchase price but also installation, training, and any necessary software.

Companies should conduct a thorough cost-benefit analysis to determine the potential

return on investment (ROI) based on their production needs and projected output.

In addition to upfront costs, ongoing operational expenses must also be taken into account.

These can include maintenance, repair, and tooling costs, which can vary significantly

depending on the complexity of the parts being manufactured. Furthermore,

energy consumption

and labor costs associated

with running the CNC machine should not be overlooked, as they can impact the overall

profitability of the investment. By carefully assessing these factors, manufacturers can

make informed decisions that align their financial resources with their production goals,

ultimately leading to a more efficient and cost-effective operation.

In the rapidly evolving landscape of CNC machining technology, staying ahead requires an understanding of future trends that will shape manufacturing decisions. One significant trend is the increasing integration of automation and artificial intelligence (AI) into CNC machining centers. According to a recent report by MarketsandMarkets, the global market for AI in manufacturing is projected to reach $10.1 billion by 2025, growing at a compound annual growth rate (CAGR) of 49.5%. This trend suggests that CNC machining centers equipped with intelligent automation capabilities can enhance productivity, reduce human error, and optimize operational efficiency, making them a prime choice for manufacturers aiming for scalability.

Another pivotal trend is the shift towards additive manufacturing and hybrid machining technologies. The Wohlers Report 2021 indicates that the additive manufacturing industry is expected to reach $35.6 billion by 2024. This growth indicates that manufacturers are increasingly looking for CNC machines that can facilitate both traditional subtractive processes and additive capabilities. Choosing a machining center that accommodates these technologies not only broadens production possibilities but also fosters innovation, allowing companies to respond swiftly to market demands and customize products more effectively. As these advanced technologies continue to develop, the importance of selecting a CNC machining center that aligns with these future trends becomes crucial for maintaining a competitive edge in the manufacturing sector.