Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Fiber Laser Cutter can feel overwhelming. Many factors come into play. According to industry expert John Smith, "Selecting the right Fiber Laser Cutter is crucial for optimizing your production." His insights guide many in the industry.

Fiber Laser Cutters vary significantly in features and capabilities. Businesses need to assess their specific requirements carefully. Consider the materials you cut most frequently. Different machines perform better with various materials. Look for user-friendly interfaces, too. A complex machine may lead to operational errors.

Investing in a Fiber Laser Cutter is not just about capability. It’s also about reliability and support. You might find yourself struggling if the machine malfunctions. Analyze the service options available. Research customer reviews, and reflect on past experiences with similar tools. A thoughtful approach will help you make a better decision.

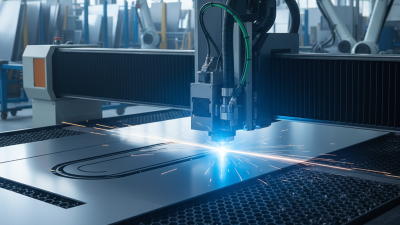

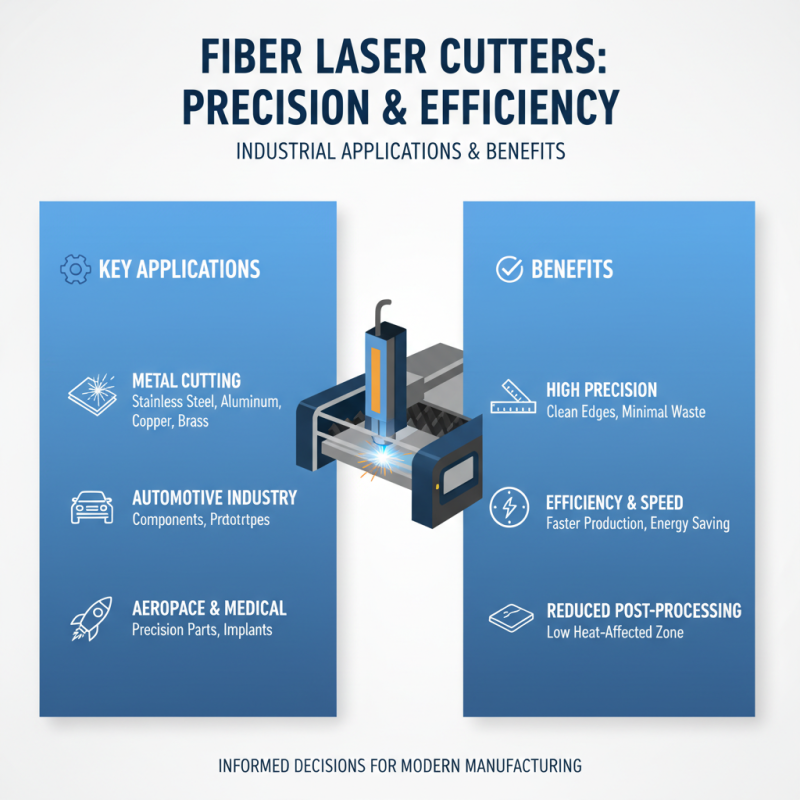

Fiber laser cutters have become essential in many industries due to their precision and efficiency. Understanding their applications can help businesses make informed decisions. These machines excel in cutting metals, including stainless steel, aluminum, and copper. They produce clean cuts with minimal heat affected zones, reducing the need for further processing.

The versatility of fiber laser cutters is impressive. They can handle intricate designs and various thicknesses. This makes them ideal for automotive, aerospace, and jewelry industries. However, not every business needs the most powerful model. Companies should evaluate their specific cutting requirements and budget. Bigger is not always better; choosing a machine that fits your needs is crucial.

Training operators can be a challenge. Technical skill is necessary to maximize these machines' potential. Maintenance is another concern. Regular check-ups are essential, yet they can be overlooked. Some businesses may find it hard to keep up with maintenance schedules. Taking the time to refine processes and train staff will pay off in the long run.

Choosing the right fiber laser cutter can be challenging. Several key factors affect your decision. Start with power requirements. Different materials need different wattages. For thin metals, a lower wattage may suffice. Thicker materials demand more power, making efficiency crucial.

Consider cutting speed and precision. A faster machine might boost production, but accuracy is vital. Look for a cutter that balances speed with quality. Additionally, evaluate the software compatibility. Good software enhances user experience and simplifies operation. If the software is complex, training may be necessary, adding time and cost.

Space is another important factor. These machines vary in size. Ensure that your workshop can accommodate the equipment comfortably. It’s easy to overlook this aspect. Finally, think about future needs. Will your business grow soon? Anticipating future requirements can save you from buying another cutter shortly. Reflect on all these points carefully; the right choice impacts your operations significantly.

When selecting a fiber laser cutter, knowing your specific cutting needs is key.

Consider the materials you will work with. Different metals, plastics, and composites require different power levels.

A lightweight cutter may suffice for thin sheets, but thicker materials demand more power.

This can affect the machine’s overall efficacy.

Think about the complexity of your designs. Intricate patterns might need a cutter with better

precision capabilities. The speed of the machine also matters. A faster cutter can

enhance productivity but may come with trade-offs in quality. Reflect on your production volume.

Are you a small shop or a large manufacturer? Your operational scale will influence the cutter's

size and capacity.

Also, consider maintenance requirements. Some machines are easier to service than others.

Downtime due to repairs can affect your bottom line. It’s crucial to weigh these aspects carefully.

Each choice has consequences for performance. Make sure to assess both immediate needs

and future growth. This will help you choose wisely.

When choosing a fiber laser cutter, it’s vital to consider various brands and models. Each brand offers unique features. Some may excel in speed, while others focus on precision. Prices can vary significantly too. Cheaper models might lack essential functions. High-end machines often come with better support and warranty options.

User reviews can reveal the real strengths of each model. Pay attention to feedback regarding ease of use and maintenance. A machine that is difficult to operate might stifle productivity. Also, reflect on your business needs. A small shop might benefit from a compact laser cutter. In contrast, a larger operation may require a high-capacity model.

Be wary of underestimating your material requirements. Certain fiber laser cutters handle specific materials better. This could impact your overall production quality. Explore different models to see what fits best. Sometimes, the perfect choice is not the most popular one. Keep an open mind, and don’t rush the decision.

| Model | Power (W) | Max Cutting Thickness (mm) | Table Size (mm) | Speed (m/min) | Weight (kg) | Price Range ($) |

|---|---|---|---|---|---|---|

| Entry-Level Model | 500 | 8 | 1300 x 900 | 20 | 500 | 10,000 - 15,000 |

| Mid-Range Model | 1000 | 12 | 1500 x 3000 | 25 | 800 | 15,000 - 25,000 |

| High-End Model | 2000 | 20 | 3000 x 1500 | 30 | 1200 | 30,000 - 50,000 |

| Industry-Specific Model | 3000 | 25 | 4000 x 2000 | 35 | 1500 | 50,000 - 80,000 |

Investing in a fiber laser cutter requires careful budgeting. The initial cost of these machines can range from $15,000 to $150,000, depending on the model and capabilities. A recent industry report indicated that about 60% of small businesses underestimate ongoing operational costs. Maintenance, electricity, and repair expenses add up over time. These hidden costs might strain a budget if not properly accounted for.

When planning your budget, consider the long-term benefits against initial costs. A high-quality machine may have a larger upfront price but could offer savings on production efficiency. For instance, fiber lasers can cut materials faster and with greater precision than traditional methods. This means lower labor costs and higher output. According to industry analytics, businesses can see a return on investment within 18 to 24 months.

Additionally, visualize your production needs. If you're focused on intricate designs or thicker materials, ensure that your budget accommodates these requirements. Underestimating the specifications can lead to costly upgrades later. Think carefully about your immediate and future needs to make an informed decision. Balancing quality and cost will ultimately shape your business's success with a fiber laser cutter.