Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In recent years, the adoption of Fiber Laser Cutters has surged significantly across various industries due to their remarkable speed, efficiency, and precision. According to a recent report from MarketsandMarkets, the global fiber laser market is projected to reach $5.18 billion by 2026, growing at a CAGR of 10.4% from 2021 to 2026. This growth is fueled by the increasing demand for laser cutting in key sectors like automotive, aerospace, and manufacturing, where the need for high-quality, intricate designs is paramount.

Choosing the right Fiber Laser Cutter for your business needs involves understanding both your production requirements and the technical specifications of available machines. As the industry evolves, factors such as wavelength, cutting speed, and materials compatibility become crucial in making an informed decision. A well-matched fiber laser cutting system not only enhances operational efficiency but also boosts the overall quality of the final products, leading to increased customer satisfaction and competitive advantage. As businesses seek to streamline their operations, investing in the right technology becomes essential for sustained growth and innovation in an ever-evolving market landscape.

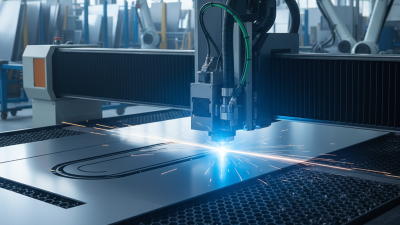

Fiber laser technology has revolutionized the cutting industry by offering precision, speed, and efficiency. Unlike traditional laser systems, fiber lasers utilize a solid-state technology that combines the power of fiber optics and advanced laser diodes, resulting in a more concentrated beam. This allows for cleaner cuts on a variety of materials, including metals, plastics, and wood. By minimizing heat-affected zones, fiber lasers can ensure high-quality cuts with minimal distortion and cleanup, making them an ideal choice for businesses aiming to enhance production quality.

Tips for selecting the right fiber laser cutter include evaluating your material types and thicknesses. Different machines are optimized for specific applications—some may excel in cutting thin sheets, while others are better suited for thicker materials. Additionally, consider the machine's cutting speed and power output, as these factors can significantly influence your overall productivity. It’s also wise to assess the maintenance needs of the laser cutter, as a well-maintained machine can lead to longer lifespan and lower operating costs.

Incorporating fiber laser technology into your workflow can also lead to reduced operational costs. For businesses looking to improve efficiency, look for features that promote automation and ease of use. Software compatibility is another critical factor; ensure that the cutter can integrate seamlessly with your existing design and manufacturing software to streamline the entire cutting process.

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Power Output | Measured in watts; affects cutting speed | Higher wattage allows for faster cutting of thicker materials | Match power to materials and thickness used |

| Cutting Area | Size of the working area of the laser cutter | Larger areas allow for cutting bigger sheets | Ensure it fits your workspace and material sizes |

| Speed and Efficiency | Cutting speed measured in meters/minute | Faster cutting increases productivity | Balance speed with precision requirements |

| Cooling System | Cooling methods to maintain laser performance | Better cooling improves performance and lifespans | Check maintenance requirements |

| Material Compatibility | Types of materials the cutter can handle | Versatility for different projects and applications | Identify your primary materials |

When selecting a fiber laser cutter, one of the most critical factors to consider is the cutting thickness and the types of materials your business plans to process. Different laser cutters have varying capabilities in terms of thickness they can effectively manage. For instance, if your business will primarily handle thin materials, a lower wattage fiber laser may suffice. However, for thicker metals such as stainless steel or aluminum, a higher wattage cutter will be necessary to achieve clean, precise cuts without compromising speed and efficiency.

Equally important is the variety of materials you intend to work with, as fiber laser cutters excel in specific applications. Metals like steel, brass, and copper respond well to fiber laser technology due to the laser's high absorption rates in these materials. Conversely, if your needs extend to non-metals like plastics or wood, you may need to explore other laser technologies or consider a multi-functional cutter. It's essential to evaluate both your current and future material requirements, as investing in a cutter that is versatile enough to adapt to different materials can significantly enhance your production capabilities and flexibility.

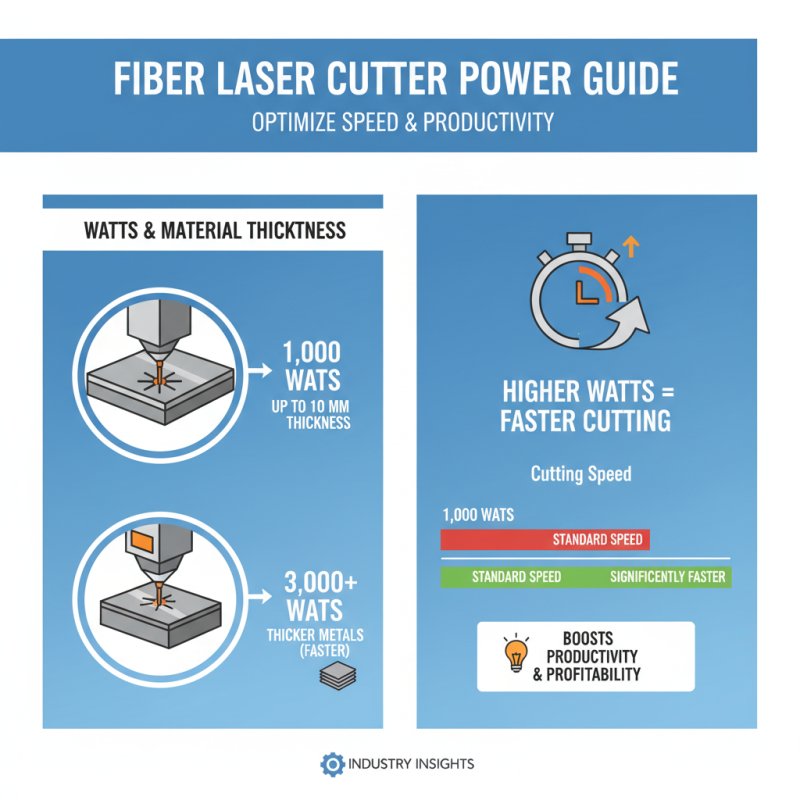

When selecting a fiber laser cutter for your business, understanding power requirements is crucial for optimizing both speed and productivity. The wattage of the laser cutter directly influences the thickness of the materials you can cut and the speed at which you can operate. According to industry reports, a machine with at least 1,000 watts can effectively cut materials up to 10 mm thick, while those in the 3,000-watt range can handle thicker metals more efficiently. Higher wattage also generally allows for faster cutting speeds, which can significantly enhance overall productivity and profitability.

Moreover, it's important to assess the speed capabilities of the fiber laser cutter. A powerful laser with lower feed rates may not meet the production demands of high-volume operations. For instance, studies show that an optimal feed rate paired with the right wattage can increase production efficiency by up to 50%. To make the best choice, businesses should evaluate their workload and consider machines capable of maintaining high speeds without sacrificing cut quality.

**Tips:** When assessing your fiber laser cutter options, calculate the average thickness of materials you intend to cut, as this will help determine the necessary wattage. Additionally, consider running time versus maintenance intervals; a machine that runs efficiently and requires less downtime will ultimately save costs. Finally, always review the production trends in your industry to ensure your investment aligns with market demands.

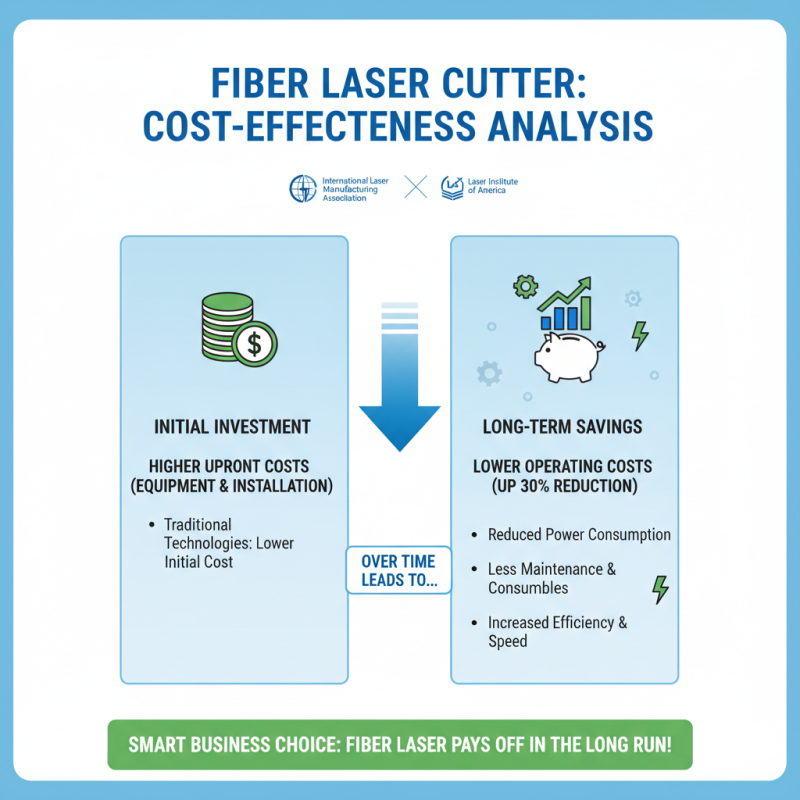

When selecting a fiber laser cutter for business needs, it's essential to conduct a thorough analysis of cost-effectiveness, particularly by comparing the initial investment with potential long-term savings. A study by the International Laser Manufacturing Association indicates that while the upfront costs for fiber laser systems can be higher than traditional cutting technologies, their efficiency and reduced operating costs often lead to significant savings over time. Fiber lasers typically consume less power and require less maintenance, which can reduce operational expenditures by up to 30%, according to the Laser Institute of America.

Moreover, the longevity of fiber laser cutters further enhances their cost-effectiveness. Reports from the National Institute of Standards and Technology suggest that fiber lasers have a lifespan that can exceed 100,000 hours of use, significantly outperforming CO2 lasers, which may require more frequent part replacements and maintenance interventions. This longevity translates into fewer downtimes and an increase in production capacity, allowing businesses to optimize their processes and improve their bottom line over the years. In the current manufacturing landscape, investing in fiber laser technology not only meets immediate production demands but also lays the groundwork for sustainable growth through increased efficiency and reduced operational costs.

When selecting a fiber laser cutter for your business needs, assessing software compatibility is crucial. A high-quality laser cutter should seamlessly integrate with existing design software, such as CAD and CAM applications. This ensures a smoother workflow, allowing for efficient design-to-manufacturing processes. It's essential to check if the cutter supports commonly used file formats, as this will save time and reduce errors during file transfers. Additionally, the ability to customize software settings provides an extra layer of flexibility, empowering users to optimize cutting parameters for specific materials and applications.

Equally important is understanding the maintenance needs of the fiber laser cutter. Regular maintenance is key to ensuring the longevity and reliability of the machine. Users should look for models that require minimal downtime for maintenance tasks, such as cleaning lenses and replacing components. A user-friendly maintenance schedule and readily available support can greatly enhance operational efficiency. Moreover, some machines offer self-diagnostic features that can alert users to potential issues before they become problematic. Prioritizing these aspects can lead to reduced operational costs and extended machine life, ultimately benefiting your business in the long run.