Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

Choosing the right High Precision Laser Cutter can significantly impact your production process. Many factors must be considered to find the best fit for your specific needs. A laser cutter is not just any machine; it’s a tool that demands careful thought and planning.

Consider your materials. Different cutters excel with various materials. If you work with metal, look for cutting power and speed. For wood, the focus may be on precision and finish quality. Visualize the projects you'll undertake. This clarity will help narrow down your options.

Don't forget about the software that supports the cutter. Compatibility can make or break your workflow. Some users overlook this aspect, leading to frustration later. Maintenance should also be on your radar. Regular upkeep ensures longevity and performance. Reflect on your workflow and project demands. Make sure your choice aligns with your future goals.

When selecting a high precision laser cutter, several factors come into play. First, consider the cutting material. Different materials require different laser types. For example, wood, metal, and acrylic all have unique properties. Knowing your primary material helps in choosing the right cutter. Additionally, think about the thickness of the materials you will work with. Thicker materials often need more powerful lasers.

Speed and accuracy are also crucial. A faster cutter isn’t always better. It’s essential to find a balance between speed and precision. High precision is vital for intricate designs. Look for a machine that offers fine adjustments to maintain cutting quality. Don't forget about maintenance requirements. Some machines need advanced upkeep, which can add to long-term costs.

It’s also useful to assess the software compatibility. Many modern laser cutters come with user-friendly software. But some may require specific programs that can be less intuitive. Reflect on your skill level and how much time you're willing to invest in learning. Often, the best choice is not the most advanced machine, but one that fits your unique needs and limits.

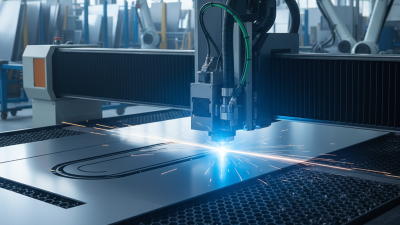

When selecting a high-precision laser cutter, understanding the technology is crucial. Several types exist, each suited for different applications. CO2 laser cutting is popular for non-metal materials like wood and acrylic. It offers smooth edges, but can struggle with metals. Fiber lasers excel in cutting metals. They are efficient and provide a clean cut, but can be more expensive.

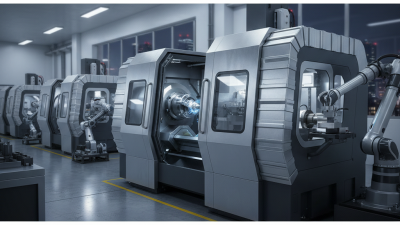

Another option is the disk laser. These are versatile and powerful, handling both metals and some non-metals effectively. However, their maintenance might be complex. Each technology has pros and cons, making your choice essential. Think about your specific needs. Consider what materials you will work with. Your budget also plays a role in the decision.

In conclusion, reflecting on the intended use is vital. Not every laser cutter fits every project. Some machines are not user-friendly for beginners. You may find that one option looks appealing but doesn’t perform as expected. Avoid rushing the decision. Take time to research and evaluate your options thoroughly. A careful choice will lead to better outcomes.

Choosing a high precision laser cutter requires careful consideration of material compatibility and thickness. Different materials react uniquely to laser cutting. For instance, acrylic can be cut cleanly at thicknesses up to 10 mm, while metals often require more powerful machines to handle thicker gauges. A recent industry report indicates that demand for laser cutters specifically for metal applications is projected to grow by 6.3% annually through 2027.

When evaluating materials, consider your projects. Wood, paper, and textiles use different settings than acrylic or metal. Using incompatible materials can yield poor results, wasting time and resources. Remember, wood may char at higher settings, while metal requires cooling systems to prevent warping.

**Tip:** Always test cut a sample before starting your main project. This can save you frustration.

Understanding thickness is crucial. Thicker materials necessitate stronger lasers and potentially longer cutting times. Many cutting projects fail because users underestimate material requirements. A general rule of thumb: if you're unsure, go for a machine that supports a broader range of materials and thicknesses.

**Tip:** Keep a detailed log of your tests with settings. This record will help refine your processes over time.

When selecting a high precision laser cutter, budgeting is crucial. The initial purchase cost often piques interest, but understanding long-term expenses is essential. Don't forget to include maintenance fees, operational costs, and potential upgrades. This can add up significantly over time. A cheaper machine might seem appealing. However, it may require frequent repairs and replacements.

Consider energy consumption too. A laser cutter's efficiency impacts your utility bills. Some machines use more power than others, increasing costs monthly. Calculate how much you will spend over a year. It's worth estimating costs for different models.

Additionally, think about the materials you'll be working with. Some cutters handle various materials better. But sometimes, specific machines are needed for specialized tasks. This could influence your budget, as well. Balancing capabilities and costs may require some compromise. Reflecting on individual needs is important. What functions are necessary for your projects?

When investing in a high precision laser cutter, after-sales support is crucial. This can make or break your experience. A well-designed machine without good support can lead to frustration. Technical assistance should be readily available. Look for companies that provide clear channels for help: phone, email, or chat.

Response time is important. Some manufacturers promise fast service but fail to deliver. Read reviews to assess their actual performance. Support personnel should be knowledgeable. Some may lack training, leaving you without the guidance you need.

Consider the resources offered. User manuals, tutorial videos, and FAQs are invaluable. However, not all companies provide thorough documentation. Testing their support before purchase can save you headaches later. Evaluate warranty options too. A solid warranty may indicate confidence in their product and support systems.