Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

Choosing the right CNC Horizontal Lathe can significantly impact your machining efficiency. Industry expert John Smith states, “Selecting the right machinery defines the quality of your output.” His words resonate with many in the machining field.

CNC Horizontal Lathes come in various sizes and capabilities, making the choice complex. Do you need high precision or high volume? Sometimes, businesses get caught up in the latest technology and forget their specific machining needs. Often, it’s the basic functions that matter most in your operations.

Consider the materials you work with. A CNC Horizontal Lathe that needs more frequent calibration can slow down production. Think about your workspace’s layout too. A larger machine can be a space hog and limit your workflow. Reflect on what you truly need to enhance your machining capabilities. Every detail counts.

CNC horizontal lathes serve various industries, from automotive to aerospace. These machines excel in producing cylindrical parts with high precision. They allow for efficient machining of materials like steel, aluminum, and plastics. Reports show that the CNC lathe market is expected to grow at a CAGR of 5.5% from 2021 to 2027. This growth reflects increasing demand for automation in manufacturing.

When considering a CNC horizontal lathe, assess its load capacity and spindle speed. A machine with higher spindle speeds can improve productivity on intricate designs. However, high speeds may cause overheating. Be mindful of cooling systems to mitigate this issue. Always check for user reviews to understand potential mechanical flaws or software limitations.

Tips: Focus on the machine's rigidity and stability. A sturdy frame enhances precision. Look for features like automatic tool changers, which save time. Regular maintenance is crucial to avoid unexpected breakdowns. Reflect on your specific needs before purchasing; a machine that is too advanced or not advanced enough can lead to inefficiency and increased costs.

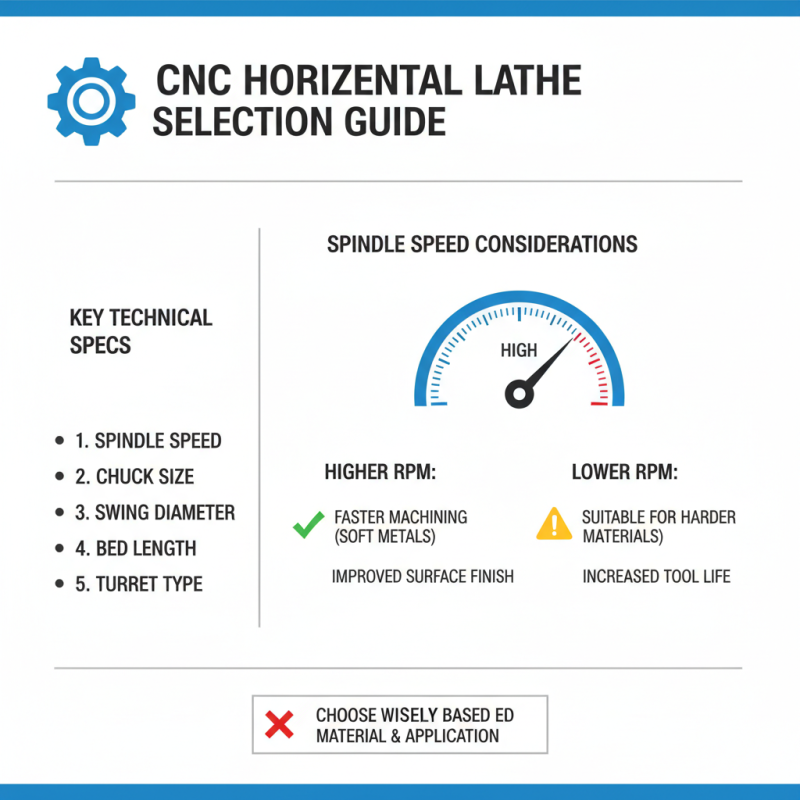

Selecting the right CNC horizontal lathe is crucial for achieving optimal machining results. One of the key factors to consider is the spindle speed. According to industry reports, high spindle speeds can significantly increase productivity. A lathe with speeds exceeding 3000 RPM is desirable for quick material removal. However, higher speeds may require more powerful motors, which can add to costs.

Another important aspect is the size and capacity of the lathe. The workpiece weight and dimensions matter immensely. Data shows that lathes with larger turning capacities can handle varied materials, ensuring versatility. For instance, a machine capable of machining parts up to 1500 mm in diameter suits a wide range of applications. But larger machines often require more floor space and investment.

While automation features, like tool changers, enhance efficiency, they can increase complexity. It’s essential to weigh the potential boost in productivity against maintenance and training needs. A balance between advanced technology and usability can define overall success. Overall, making an informed decision by considering specific machining needs leads to better outcomes.

| Key Factor | Description | Importance Level |

|---|---|---|

| Size and Capacity | Consider the maximum swing diameter and length of the workpiece needed. | High |

| Precision and Tolerance | Evaluate the machine's ability to maintain tight tolerances. | Critical |

| Ease of Use | Look for user-friendly controls and software for programming. | Medium |

| Power and Torque | Assess the spindle power and torque ratings for heavy cutting operations. | High |

| Tooling Options | Consider the compatibility with various tooling systems and attachments. | Medium |

| Durability and Build Quality | Evaluate the construction materials and general durability of the lathe. | High |

| Support and Maintenance | Check for availability of service and support, as well as spare parts. | Medium |

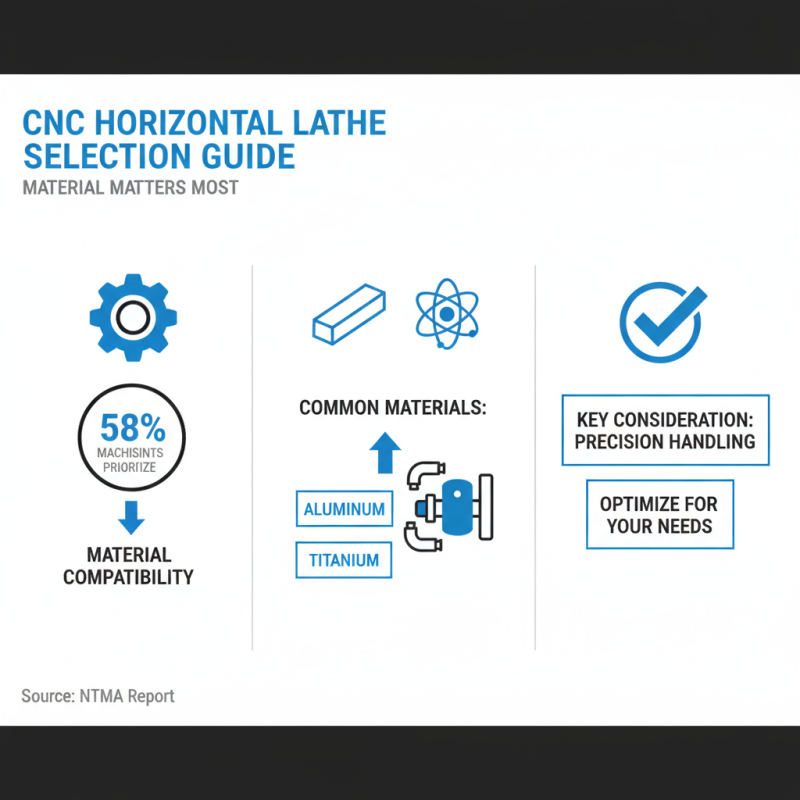

When selecting a CNC horizontal lathe, understanding your machining needs is paramount. Start by assessing the materials you will work with. A report from the National Tooling and Machining Association indicates that 58% of machinists prioritize material compatibility in their purchase decisions. If you primarily work with metals like aluminum or titanium, ensure the lathe can handle these with precision.

Next, consider the component sizes you typically manufacture. A lathe's swing over bed and distance between centers dictate its capacity. According to the American Society of Mechanical Engineers, 72% of companies have faced production delays due to inadequate machine size. Additionally, explore the spindle speed ranges. Higher speeds can enhance productivity but may lead to quality issues if not matched with proper tooling.

Another crucial point is automation features. Many modern lathes offer advanced capabilities, which can boost efficiency significantly. However, training is necessary to maximize these features. Industry data reveals that 60% of operators struggle with automation settings at first. This highlights the importance of investing in operator education alongside machine selection. Reflect on your specific requirements carefully to make an informed choice.

When evaluating CNC horizontal lathes, technical specifications are crucial. Pay attention to the spindle speed. A higher speed allows for faster machining. However, it may not be suitable for all materials.

Next, consider the swing over bed and over carriage dimensions. These measurements directly impact the maximum diameter of parts you can work on. If your projects often involve larger parts, ensure the lathe's specifications meet your needs.

Furthermore, the control system matters. User-friendly interfaces can save time and reduce errors. Often, owners underestimate the learning curve associated with advanced controls. Make sure to weigh the trade-offs between features and ease of use. Keep these factors in mind while choosing the right CNC horizontal lathe for your tasks.

When selecting a CNC horizontal lathe, budget considerations are crucial. A high-quality machine often comes with a significant price tag. Industry reports show that a basic CNC lathe can start at around $20,000, while advanced models can exceed $100,000. This means careful financial planning is essential for small to medium enterprises.

Cost-effectiveness is not just about the initial purchase price. Maintenance and operational costs can add up. According to a study by the Precision Machining Association, companies can spend 15% of their total equipment cost annually on maintenance. It's vital to factor this into your overall budgeting strategy.

Tips: Assess your production volume. A machine that is too advanced for low-output jobs may waste resources. Invest in training for your staff. Operator expertise can prolong machine life and enhance performance. Lastly, compare features critically. Sometimes, a less expensive model with fewer capabilities may meet your needs perfectly, saving you money in the long run.