Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving world of manufacturing, the **Fiber Laser Cutter** stands out for its precision and efficiency. As industries strive for high-quality output, these machines play a crucial role. They are not just tools; they are a gateway to innovation.

When considering the best fiber laser cutter options for 2026, one must reflect on various factors. The technology is advancing rapidly. Each model offers unique features catering to specific needs. This diversity can make choosing the right cutter difficult. Moreover, understanding one's requirements is essential.

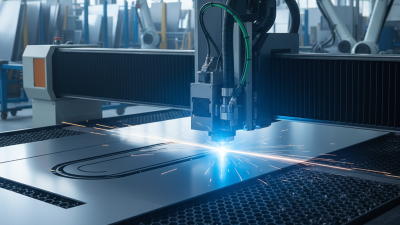

A fiber laser cutter can significantly enhance productivity. It can cut through metal, wood, and other materials with ease. However, not all machines are created equal. Some may lack durability or efficiency, leading to frustration. It's vital to evaluate both power and design. Selecting the wrong tool can hinder progress. Therefore, careful consideration is key when investing in this technology.

When selecting a fiber laser cutter, several top features stand out.

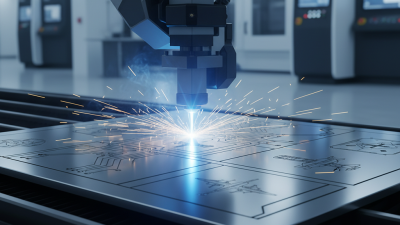

Precision is vital. Look for machines with high-quality optics. This ensures tighter cutting tolerances.

Efficiency comes from speed and power. A good cutter should deliver fast processing times while maintaining clean cuts.

Consider the material compatibility as well. A versatile cutter can handle various materials, from metals to plastics. This flexibility boosts productivity.

Some machines even offer advanced cooling systems, preventing overheating during intensive tasks.

User-friendly interfaces are essential. Operators should easily navigate controls and settings. Some models may have their quirks that require extra training.

Maintenance should not be ignored, either. Routine checks ensure long-lasting performance. Yet, many users overlook this, leading to unplanned downtimes.

Investing time in understanding these features can streamline operations significantly.

When exploring fiber laser cutters, precision and efficiency are crucial. Many brands offer various features and capabilities. Some machines excel in speed, while others focus on detail. Each brand brings something unique to the table. Users must consider their specific needs when making a choice.

Some machines provide advanced cooling systems. This feature can enhance performance but may also lead to higher maintenance costs. Others prioritize user-friendly interfaces. While these are great for beginners, they might lack advanced features that professionals require. Quality varies among brands, and some may fall short in durability.

It's important to test machines before purchasing. Many users have reported issues with consistency over time. A machine might perform well initially, but performance can decline. This inconsistency can be frustrating, especially in high-stakes projects. Buyers should reflect on their long-term needs and not just focus on immediate performance.

Fiber laser cutters are making significant strides in various industries. The automotive sector, for instance, extensively uses these machines for cutting intricate parts. A report by MarketsandMarkets noted that the demand for laser cutting in automotive applications will grow steadily, reaching a market size of over $2.5 billion by 2025.

In the aerospace industry, precision is crucial. Fiber lasers offer exceptional accuracy for components like brackets and fittings. They can handle tough materials like titanium and aluminum effectively. According to a study published by Research and Markets, the aerospace laser cutting market is expected to grow at a CAGR of around 6% through 2027, highlighting the increasing reliance on advanced laser technologies.

While fiber laser cutters offer many advantages, there are challenges to consider. Some machines may require specific training for operators, leading to increased upfront costs. Additionally, maintenance is essential for long-term operation. Companies must invest in training to ensure efficient use. Despite these hurdles, the promise of efficiency and precision keeps driving industries towards fiber laser technology.

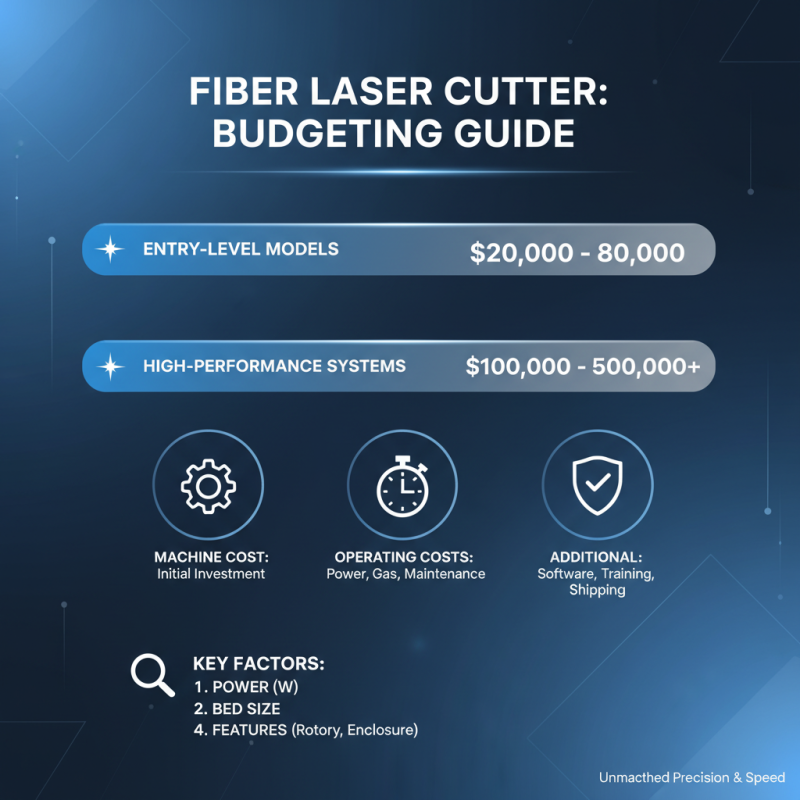

When budgeting for a fiber laser cutter, several factors come into play. The initial cost of the machine can vary widely. On average, entry-level models start at around $20,000. Meanwhile, high-end systems can exceed $500,000, depending on the required functionality. These machines offer unmatched precision and speed, but it's vital to assess your specific needs.

Maintenance costs also need consideration. Regular servicing may cost between $1,000 to $3,000 annually. Laser replacements could be an additional expense, ranging from $5,000 to $20,000 every few years. According to industry reports, companies often overlook these expenses, leading to budget surprises.

Training staff is another expense that often goes unaddressed. A well-trained operator can greatly enhance productivity and efficiency. The average training program costs about $2,000 per employee. Investing in upskilling can reduce operational mistakes, which might save companies from costly errors in the long run. Evaluating these elements is crucial for making an informed financial decision.

Maintenance plays a vital role in maximizing the performance of fiber laser cutters. Regular upkeep ensures that these machines operate efficiently and precisely. According to a report by the Laser Institute of America, proper maintenance can reduce downtime by up to 30%. This reduction is crucial for maintaining productivity in competitive environments.

One essential tip is to keep the optics clean. Dirty lenses can scatter the beam, leading to poor cutting quality. A simple cleaning schedule can significantly enhance performance. Regularly inspect the fiber alignment as well. Misalignment can cause inconsistent cuts, which impacts the entire production line. Many users overlook this detail, yet it is pivotal for maintaining accuracy.

Another factor to consider is software updates. Technology evolves quickly. Automated updates ensure that the cutter benefits from the latest algorithms for efficiency. Failure to update can lead to outdated performance. According to industry studies, updated software can enhance machine efficiency by nearly 20%. Neglecting these maintenance tips may seem minor, but the cumulative effects can hinder operational success.