Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving world of precision engineering, the significance of selecting the right CNC milling machine cannot be understated. Renowned industry expert and CNC specialist, Dr. Emily Chen, emphasizes that "the accuracy of your machining process heavily relies on the quality and capabilities of your CNC milling machine." This assertion underlines the critical role that advanced CNC milling technology plays in achieving high precision and efficiency in manufacturing.

As we delve into 2023, the landscape of CNC milling machines is filled with remarkable innovations that cater to various engineering needs. From enhancing productivity to ensuring intricate designs are accurately brought to life, the best CNC milling machines stand out for their reliability and technological advancements. In this guide, we will explore the ten best CNC milling machines available this year, revealing the essential features that make them indispensable tools for engineers and manufacturers alike. Whether you are a seasoned professional or a newcomer to the machining world, understanding these machines will empower you to make informed decisions that elevate your engineering projects to new heights.

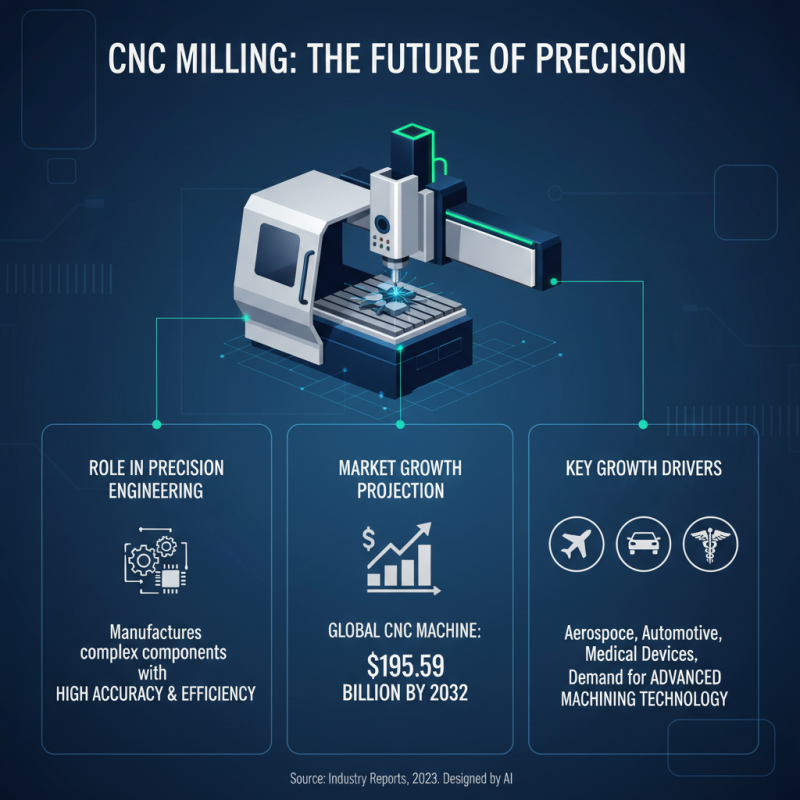

CNC milling machines play a critical role in precision engineering, enabling manufacturers to produce complex components with high accuracy and efficiency. The growing demand for precision engineering solutions is reflected in the projected expansion of the global CNC machine market, expected to reach $195.59 billion by 2032. This growth is driven by the need for advanced machining technology, particularly in sectors like aerospace, automotive, and medical devices.

Tips for selecting the right CNC milling machine include assessing the specific application requirements, understanding the importance of machine accuracy, and evaluating the technological features that can enhance productivity. It’s vital to consider multi-axis capabilities and automation options, which can significantly reduce production time and costs.

As technology continues to evolve, AI is significantly reshaping the CNC machine tools market, introducing new features that improve operational efficiency and facilitate precise manufacturing processes. Keeping up with these advancements will be essential for engineers looking to optimize their production capabilities and maintain a competitive edge in the market.

When selecting a CNC milling machine, several key features must be considered to ensure optimal performance in precision engineering. First and foremost, the machine's accuracy and repeatability are crucial for achieving tight tolerances. According to a recent industry report, machines capable of operating at tolerances within ±0.005 mm are preferred for high-precision tasks. Additionally, spindle speed plays a significant role; higher spindle speeds (over 10,000 RPM) can improve machining efficiency and surface finish quality, making them a vital parameter in CNC milling machines.

Another important aspect to evaluate is the machine's rigidity and stability, which are essential for minimizing vibrations during operation. A robust machine design correlates with better surface quality and extends tool life, significantly impacting production efficiency. Furthermore, the software capabilities integrated with the milling machine, including CAD/CAM compatibility, influence the overall workflow, enabling smoother transitions from design to production. Overall, understanding these critical features ensures that the selected CNC milling machine meets both current and future engineering demands.

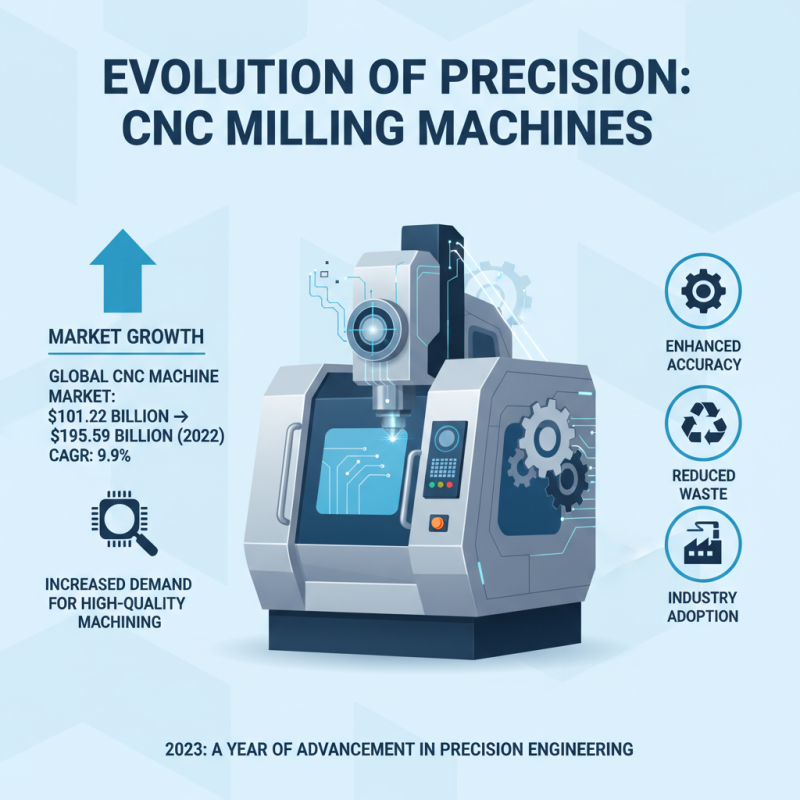

In 2023, the landscape of CNC milling machines has continued to evolve, reflecting significant advancements in precision engineering. This growth can be partially attributed to the projected expansion of the global CNC machine market, which is expected to increase from $101.22 billion in 2025 to $195.59 billion by 2032, showcasing a robust CAGR of 9.9%. Such growth emphasizes the increasing demand for high-quality machining processes across industries, which rely heavily on CNC technology to enhance accuracy and reduce waste.

The benefits of precision engineering in sectors like construction and manufacturing are profound. With ongoing innovations in CNC milling technology, modern machines now incorporate advanced data model-based toolpath generation techniques. These developments allow for the efficient use of point cloud models, significantly improving machining processes. As industries continue to prioritize quality and efficiency, the role of CNC milling machines becomes more crucial, setting the stage for the top 10 machines of 2023 to redefine standards for precision and performance in engineering applications.

In the realm of precision engineering, the choice of a CNC milling machine significantly influences manufacturing outcomes. According to a 2022 report by MarketsandMarkets, the global CNC milling machine market is projected to reach USD 100 billion by 2027, driven by advances in technology and increased demand in sectors like aerospace and automotive. When comparing the best CNC milling machines of 2023, key performance indicators include cutting speed, accuracy, and material versatility. Machines from renowned brands such as Haas and DMG Mori are consistently lauded for their high-speed machining capabilities, achieving up to 30,000 RPM, significantly reducing cycle times.

Moreover, an evaluation of different CNC milling systems highlights the importance of rigidity and thermal stability. A study conducted by the American Society of Mechanical Engineers (ASME) found that advanced materials in machine construction can enhance tool longevity and reduce maintenance costs. For instance, machines that utilize polymer concrete bases demonstrate improved vibration dampening and thermal performance. With these attributes in mind, engineers are better equipped to select milling machines that not only meet precision requirements but also optimize production efficiency, ensuring an effective return on investment in a competitive market.

When selecting CNC milling machines for precision engineering, user reviews and industry feedback play a critical role. In a recent survey conducted by the Association for Manufacturing Technology, 76% of respondents expressed that the reliability of their CNC equipment is paramount, identifying precision as a top priority in their operations. Key features praised by users include the machines' ability to maintain tight tolerances and the efficiency of integrated software for optimal performance. Specific models like the Haas VF series garnered significant attention, with 89% of users recommending them for their consistent results and ease of operation.

Moreover, industry feedback indicates an increasing trend towards automated systems. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2028, driven by advancements in automation and technology. Users highlight the importance of machine learning capabilities in their CNC systems, which allows for real-time adjustments and enhances overall productivity. Such insights emphasize that as precision engineering evolves, user experiences remain vital for manufacturers aiming to optimize their offerings and meet the demanding standards of the market.