Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

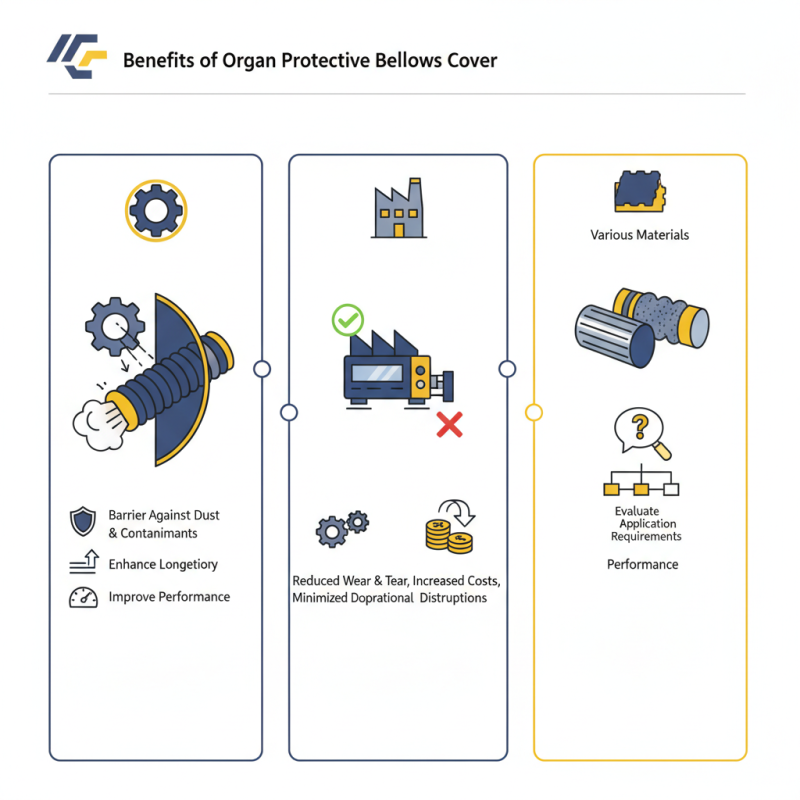

Organ Protective Bellows Cover plays a crucial role in machinery protection. These covers act as a barrier against dust, dirt, and other contaminants. By safeguarding the moving parts of equipment, they enhance longevity and performance.

Industries benefit significantly from these protective covers. They reduce wear and tear, minimizing downtime for repairs. A well-maintained machine shows improved efficiency. On the other hand, neglecting this aspect can lead to increased costs and potential operational disruptions.

The design of Organ Protective Bellows Cover also adds to their effectiveness. With various materials available, they suit many environments. However, users must reflect on their specific needs. Evaluating application requirements is vital for optimal performance and protection.

Organ protective bellows covers are vital for extending the life of machinery. They shield delicate components from dust, moisture, and harmful debris. These covers help maintain cleanliness in critical areas, reducing the risk of breakdowns.

When machinery operates in harsh conditions, wear and tear is inevitable. Protective bellows mitigate this effect by absorbing impacts and preventing contaminants from infiltrating sensitive areas. It’s significant to note that even small debris can lead to major issues. Regular maintenance alone may not be enough without these protective covers.

However, it’s easy to overlook the importance of these simple components. Equipment managers might prioritize other upgrades instead. This mindset can lead to increased repairs and shortened equipment life. Investing in bellows covers could save time and money in the long run. Consider the potential cost of machinery failure versus the affordable installation of covers. The benefits are clear when we reflect on the future health of our equipment.

In industrial settings, safety is paramount. Organ protective bellows covers play a crucial role in enhancing safety. These covers shield vital machinery parts from dust, debris, and accidental damage. They are often used on moving parts like slide rails and ball screws. By preventing exposure, they prolong equipment life and efficiency.

When installed, bellows covers offer a visible barrier. Workers can easily see that a machine is protected. This visibility reduces the likelihood of accidents. Yet, some may overlook their importance until it's too late. Regular checks are necessary to ensure they are intact. If wear or damage is ignored, the risks increase.

Implementing bellows covers requires training. Workers must understand their placement and maintenance. Unfortunately, some may not grasp the need for consistent upkeep. While the covers seem straightforward, their effectiveness hinges on proper application. The challenge remains to keep safety practices at the forefront of everyone's mind.

| Benefit | Description |

|---|---|

| Protection Against Contamination | Helps to prevent dirt, dust, and other contaminants from entering machinery or sensitive areas. |

| Enhanced Safety | Reduces the risk of accidents by covering moving parts, preventing accidental contact. |

| Durability | Made from robust materials that can withstand harsh industrial environments. |

| Cost-Effective Maintenance | Reduces the need for frequent repairs and maintenance by protecting equipment. |

| Versatility | Can be used across various types of machinery and equipment. |

Organ protective bellows covers play a crucial role in reducing maintenance costs for machinery. These covers provide a barrier against dust, debris, and other contaminants. By protecting vulnerable components, they extend the lifespan of machinery. As a result, businesses can save money on frequent repairs and replacements. This leads to improved operational efficiency and reduced downtime.

Maintenance costs can escalate quickly if machinery is not protected. Regular inspections become necessary, and replacements can become expensive. Bellows covers minimize wear and tear on important parts. They help maintain optimal performance, which can significantly lower shop floor expenses. Investing in protective covers can pay off in the long run.

Tip: Regularly check the integrity of your bellows covers. A small tear can lead to larger problems over time. Watch for signs of wear, and replace them proactively.

Another tip is to clean the covers regularly. Accumulated debris can hinder their protective function. Simple maintenance can save you from costly machinery issues. The longer you wait, the higher the expense.

Organ protective bellows covers are essential in various industries, safeguarding complex machinery from environmental hazards. They are made from materials like PVC, polyurethane, and rubber. Each material brings unique advantages. For instance, PVC offers waterproof properties, while polyurethane is known for its abrasion resistance. This makes each material suitable for different operational settings.

According to a recent industry report, rubber coatings can extend the lifespan of mechanical components by up to 30%. In sectors such as construction and manufacturing, this lifespan is crucial. However, not all materials perform equally in extreme conditions. Some may degrade faster when exposed to UV light or extreme temperatures. It's essential for manufacturers to choose the right material based on specific environmental challenges.

Additionally, the economic impact of using high-quality materials is notable. A study indicated that investing in superior bellows covers could reduce maintenance costs by as much as 25%. Yet, it's vital to continually assess how these materials perform over time. Regular evaluations can help identify wear and potential failure points. This vigilance ensures that companies can make informed decisions, safeguarding both equipment and investments.

Organ protective bellows covers are vital in various industries. These covers shield sensitive equipment from dust, debris, and harsh environments. In the manufacturing sector, for instance, the global bellows cover market is projected to grow significantly. A report from Market Research Future highlighted a growth rate of around 5.8% annually. This signals increasing awareness of protecting machinery.

In the automotive industry, these covers play a crucial role. They keep components safe during production and assembly. Data from the Automotive Industry Association shows that 20% of machinery downtime results from environmental damages. The cost of repairs can be substantial. Implementing organ protective bellows covers helps reduce these expenses significantly.

However, not all installations are perfect. Some users report challenges with fitting and compatibility. The right choice can require careful thought. Prioritizing quality over cost often leads to better outcomes. Investing in suitable bellows covers fosters long-term efficiency, despite initial complexities. Adaptation to unique needs remains an ongoing journey. This reinforces the importance of continued industry feedback and improvement.