Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

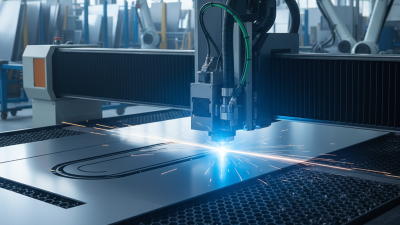

The demand for High Precision Laser Cutters is rapidly growing in various industries, including automotive, aerospace, and electronics. According to a recent report by MarketsandMarkets, the global laser cutting market is projected to reach $9.5 billion by 2026, with a compound annual growth rate (CAGR) of 6.5%. This significant growth highlights the importance of precision in manufacturing processes, where the accuracy of cuts can determine product quality and efficiency.

Industry expert Dr. Emily Shaw, a leading figure in laser technology, states, "The advancements in High Precision Laser Cutters have revolutionized manufacturing, enabling more intricate designs and finer details." These machines not only enhance productivity but also offer unmatched versatility. They can handle various materials, from metals to plastics, allowing for tailored solutions across sectors.

However, companies must remember that investing in high precision technology comes with challenges. The initial cost can be high, and operators require proper training. Moreover, continuous maintenance is essential to ensure optimal performance. As the industry evolves, the balance between innovation and practicality is a critical consideration for achieving long-term success in laser cutting applications.

High precision laser cutters are essential tools for various industries. In 2026, these machines will offer advanced features that enhance performance and efficiency. One notable feature is improved beam quality. This leads to cleaner cuts and reduced material waste. Manufacturers are focusing on creating systems that provide consistent results with minimal errors.

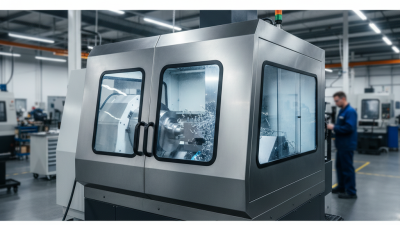

Another critical aspect is speed. Modern laser cutters can operate faster than ever before. This capability increases production efficiency and meets tight deadlines. Adding automation to these machines can further streamline the cutting process. Operators can focus on quality control while machines handle repetitive tasks.

Tip: When selecting a laser cutter, consider the type of materials you work with. Different lasers excel in cutting metals, plastics, or wood. It’s also vital to evaluate the cooling systems of the machines. Overheating can affect precision and performance.

Durability is another factor to watch. While many cutters look robust, not all materials withstand long-term use. Regular maintenance is essential. Small issues can escalate, leading to costly repairs. Keeping an eye on the machine’s parts ensures longevity.

Tip: Invest in training for operators. Even the best machines can underperform without skilled hands. This investment pays off in efficiency and safety. Continuous learning keeps your team updated on the latest technology, ensuring optimal results.

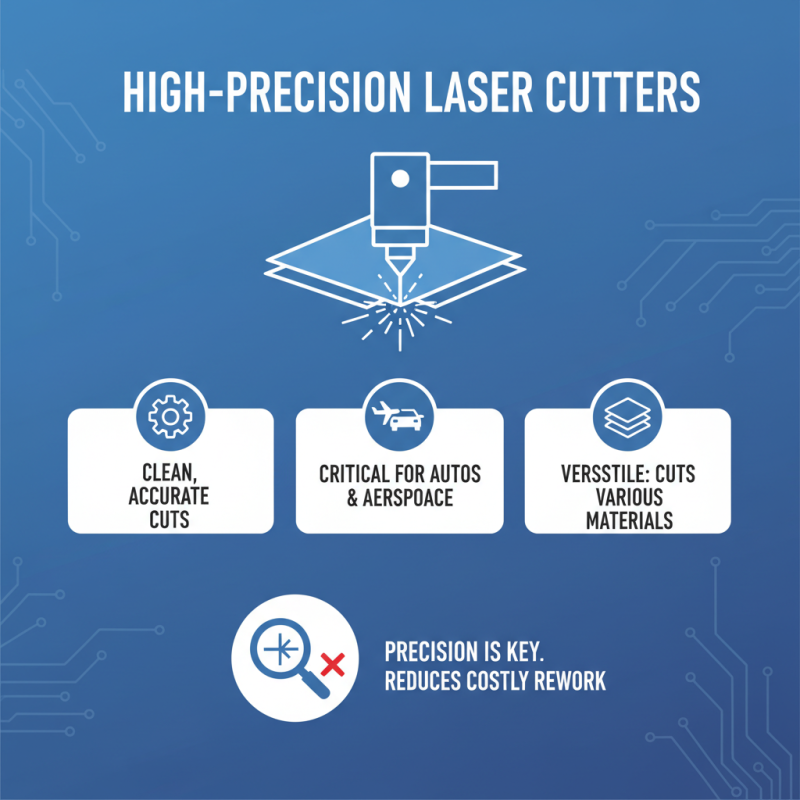

High precision laser cutters have transformed various industries, offering significant benefits. These machines produce clean, accurate cuts. This is essential for industries such as automotive and aerospace. The ability to cut through different materials, like metals and plastics, adds versatility. Precision is key here. Even a small error can lead to costly reworks.

In manufacturing, high precision is crucial. For example, in electronics, tiny components must fit perfectly. Mistakes can cause product failure. Laser cutting minimizes such risks. The process is efficient, reducing waste material. This is better for the environment and the budget. However, operators must be trained properly. Misuse can lead to damage or injury.

The benefits extend to the creative sector as well. Artists and designers use these tools for intricate designs. High precision allows for unique creations. But there's a challenge in balancing creativity and practicality. Sometimes, the intricate designs take longer to produce. This could lead to missed deadlines. It's a delicate dance between quality and efficiency. Embracing high precision laser cutting can lead to amazing results, but careful consideration is crucial.

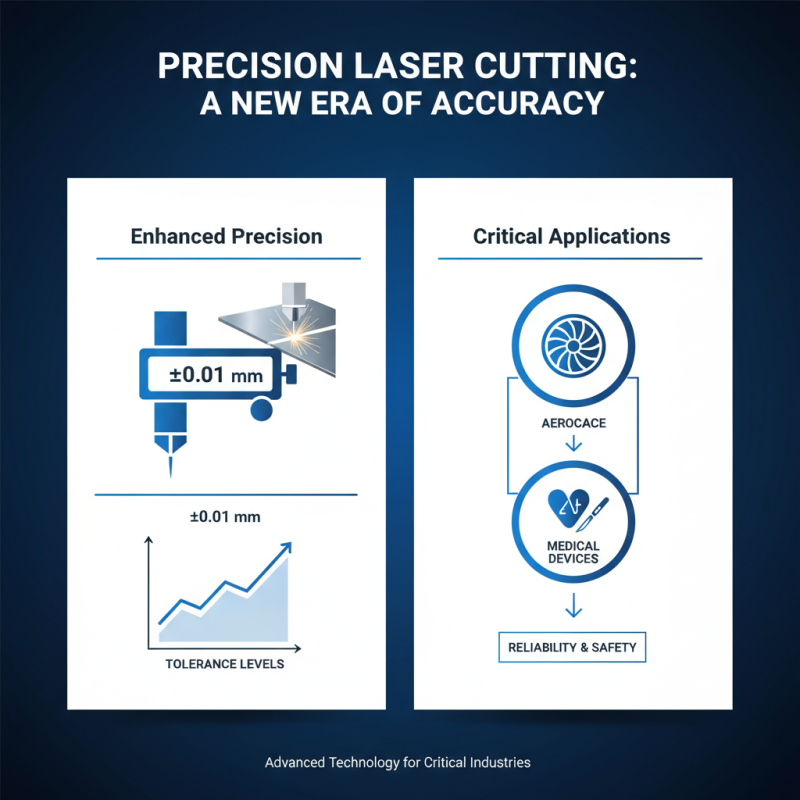

The advancement in laser cutting technology has significantly enhanced precision in various industries. In recent years, reports indicate that precision laser cutters can achieve tolerance levels of up to ±0.01 mm. This level of accuracy is vital for applications in aerospace and medical device manufacturing, where even minor deviations can lead to critical failures.

The integration of advanced software and machine learning has optimized the cutting process. Data from industry studies show that laser cutting speed can increase by up to 30% when paired with intelligent systems. These systems analyze real-time data to adjust beam focus automatically. This reduces waste and improves efficiency, yet it demands continuous operator training. There remains the challenge of keeping up with software updates. Many users face difficulties in mastering the latest features.

Despite these advancements, imperfections can still occur. Factors like material variability and environmental conditions can affect outcomes. A recent survey revealed that 20% of manufacturers reported quality issues linked to inconsistent material properties. Reflecting on these challenges is crucial for ongoing improvement in the industry.

Investing in high precision laser cutters can be a game-changer for businesses. However, cost considerations are critical. These machines might require a substantial initial investment. Maintenance costs also add up over time. It's essential to assess if these expenses align with your budget.

Tips: Always consider financing options. Seek out grants or incentives for implementing new technology. This can dramatically enhance your return on investment.

Analyzing the return on investment (ROI) is vital. Laser cutting technology often results in reduced waste and improved efficiency. However, it’s not a one-size-fits-all solution. Some businesses may experience a slower ROI due to technical challenges. Make sure to evaluate your unique operational needs before making a commitment.

Tips: Take time to research industry trends. Join forums or groups where you can learn from other businesses’ experiences. This can offer valuable insights into potential pitfalls.

In 2026, several high precision laser cutters dominate the market. These machines offer exceptional accuracy and speed for various applications. Their advanced features make them invaluable for businesses aiming to enhance production efficiency. Key aspects include the wattage of the laser, software compatibility, and ease of operation. Brands showcase different strengths in cutting a range of materials, from metals to plastics.

When comparing top brands, look for user-friendly interfaces. A simpler control system can reduce training time and minimize errors. Maintenance also differs, with some brands requiring more frequent service than others. Consider the cost-effectiveness of consumables, as this can impact overall expenses.

Tips: Regularly review machine performance. Small issues may indicate larger problems. Invest time in understanding machine settings for optimal results. Always stay informed about software updates; they can significantly enhance performance.