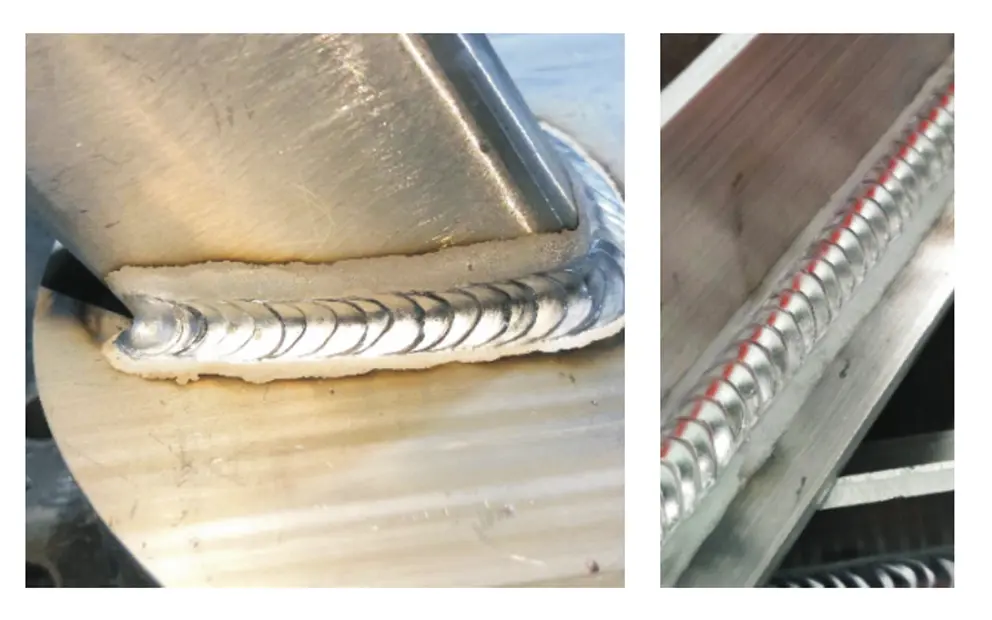

Aluminum Alloy Welding

SCOPE OF APPLICATION

2.5mm-14.0mm aluminum or aluminum alloy

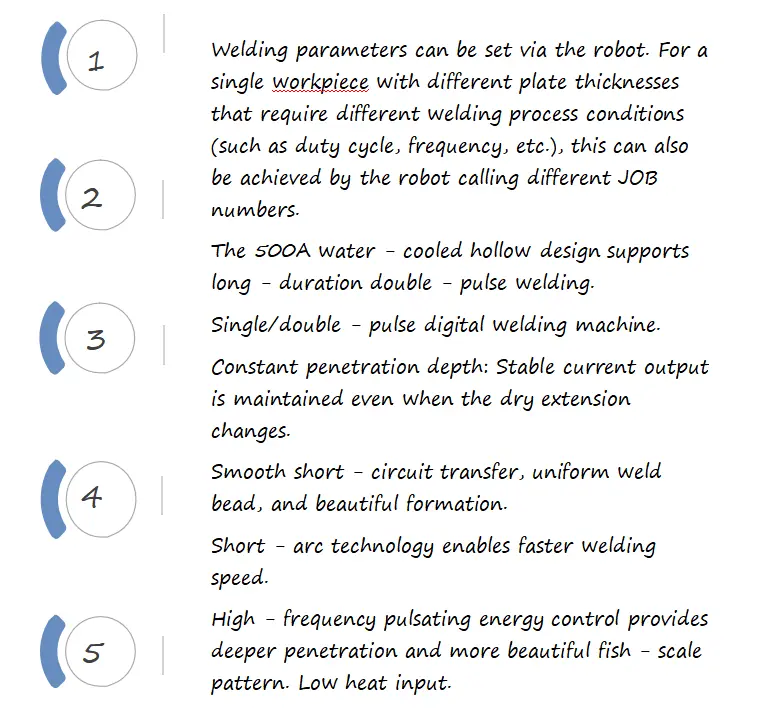

FEATURES

PARAMETER

|

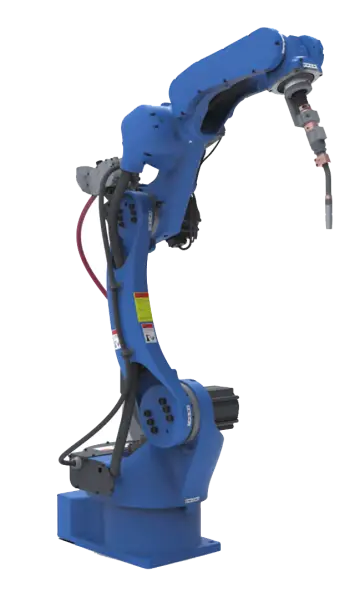

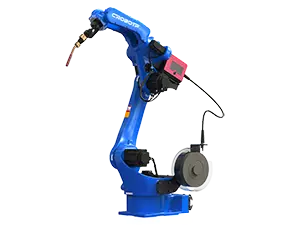

CRP-RH14-10-W Welding robot |

|||

|

Arm Type |

Vertical Multi - Joint |

||

|

Degrees of Freedom of Movement |

6 - axis |

||

|

Maximum Payload |

10KG |

||

|

Max. Stroke |

Axis 1 |

Front - Mounted / Inverted: - 167° - 167°, Wall - Mounted: - 30° - 30° |

|

|

|

Axis 2 |

0° - 175° |

|

|

|

Axis 3 |

- 80° - 150° |

|

|

|

Axis 4 |

- 190° - 190° |

|

|

|

Axis 5 |

- 105° - 130° |

|

|

|

Axis 6 |

- 210° - 210° |

|

|

Max. Speed |

Axis 1 |

169°/S |

|

|

|

Axis 2 |

169°/S |

|

|

|

Axis 3 |

169°/S |

|

|

|

Axis 4 |

280°/S |

|

|

|

Axis 5 |

240°/S |

|

|

|

Axis 6 |

520°/S |

|

|

Allowable Torque |

Axis 4 |

10N.m |

|

|

|

Axis 5 |

10N.m |

|

|

|

Axis 6 |

3N.m |

|

|

Allowable Inertia Torque |

Axis 4 |

0.25kg.m² |

|

|

|

Axis 5 |

0.25kg.m² |

|

|

|

Axis 6 |

0.05kg.m² |

|

|

Repeatability Positioning Accuracy |

±0.08mm |

||

|

Maximum Reach |

1440mm |

||

|

Weight of the Robot |

170KG |

||

|

Installation Method |

Floor - Mounted, Ceiling - Mounted |

||

|

Installation Environment |

Ambient Temperature |

0 - 45°C |

|

|

|

Relative Humidity |

20 - 80% (Non - Condensing) |

|

|

|

Vibration |

Below 0.5G |

|

|

|

Others |

The robot installation site must be away from: Flammable or corrosive liquids or gases, electrical interference sources |

|

|

IP Rating |

Robot body: IP54, Wrist: IP67 |

||

|

Features |

Compact structure, high - speed, high - precision, high - expandability, easy to operate |

||

|

Application Scenarios |

Welding, cutting, assembly, handling, marking, grinding |

||

|

CRP-E60-G4 Electrical cabinet |

|

|

Teach Pendant |

8 - inch TFT - LCD, keyboard + touch screen, mode selection switch, safety switch, emergency stop button, cable length 6m |

|

User Storage |

200M |

|

Number of Controlled Axes |

6 + 2 axes (6 - axis standard configuration, external axes are optional) |

|

Interfaces |

Digital I/O Interface ,22 - way input / 22 - way output, COM expandable |

|

|

4 - channel 0 - 10V analog output, 12 - bit accuracy, COM expandable |

|

|

Dual - channel encoder signal interface (for position tracking) |

|

|

Ethernet interface |

|

|

Dual USB interfaces |

|

Operation Modes |

Teach, playback, remote |

|

Motion Functions |

Point - to - point, linear, circular arc |

|

Instruction System |

Motion, logic, process, arithmetic |

|

Coordinate Systems |

Joint coordinate, Cartesian coordinate, user coordinate, tool coordinate, base coordinate |

|

Abnormality Detection Functions |

Emergency stop anomaly, servo anomaly, user coordinate anomaly, tool coordinate anomaly, safety maintenance, arc - starting anomaly, etc. |

|

Robot Safety |

External emergency stop, anti - collision, safety pin interfaces; MC safety loop, servo softening, etc. |

|

Reserved Dedicated Interfaces |

Special interfaces for arc welding, workstation interfaces, Remote host - side interfaces |

|

Software Packages |

Welding / handling / palletizing / painting, etc. (optional) |

|

Others |

Built - in PLC, power - off recovery, encoder interface (supports synchronous belt), arc tracking and accessories (optional), vision software (optional), laser tracking software (optional), etc. |

|

Interconnection Cable between Cabinet and Robot Body |

5m |

|

Power Supply |

3 - phase 380VAC 50 - 60HZ |

|

Dimensions |

550X785X410mm |

|

Weight |

65KG |

|

BINGO 350IIR Welding Machine |

|

|

Control Mode |

Digital Control |

|

Rated Input Voltage/Phase Number |

3 - phase 380V AC |

|

Input Power Frequency |

50Hz |

|

Rated Input Capacity |

17.1KVA |

|

Welding Wire Diameter |

0.8, 1.0, 1.2 |

|

Wire Feeding Type |

Floating / Floating |

|

Rated Input Current |

26A |

|

Rated Output Voltage |

31.5V |

|

Rated Duty Cycle |

60% |

|

Rated Output No - load Voltage |

85V |

|

Output Current Range |

20A - 350A |

|

Output Voltage Range |

14V - 40V |

|

Enclosure Protection Level |

IP21S |

|

Ambient Temperature |

- 10°C - 40°C |

|

Insulation Class |

H/B |

|

Accessory parameters |

|

|

Welding Torch |

500A air - cooled torch, 100% duty cycle |

|

Welding Torch Angle |

Gooseneck 22° |

|

Anti - collision |

Recovery accuracy 0.1mm |

|

Wire Feeding Tube Length |

1.8m |

|

Positive Welding Cable |

3m (50mm2/70mm²) |

|

Negative Welding Cable |

3m (50mm2/70mm²) |

|

Wire Feeder Control Cable |

5m |

|

Operation Box |

Includes emergency stop, start, pause, enable. Cable length 5m, 2 pieces standard - equipped |

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products